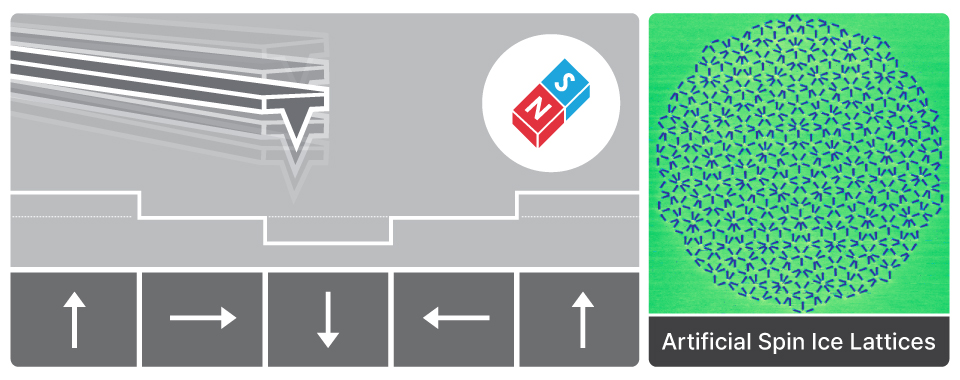

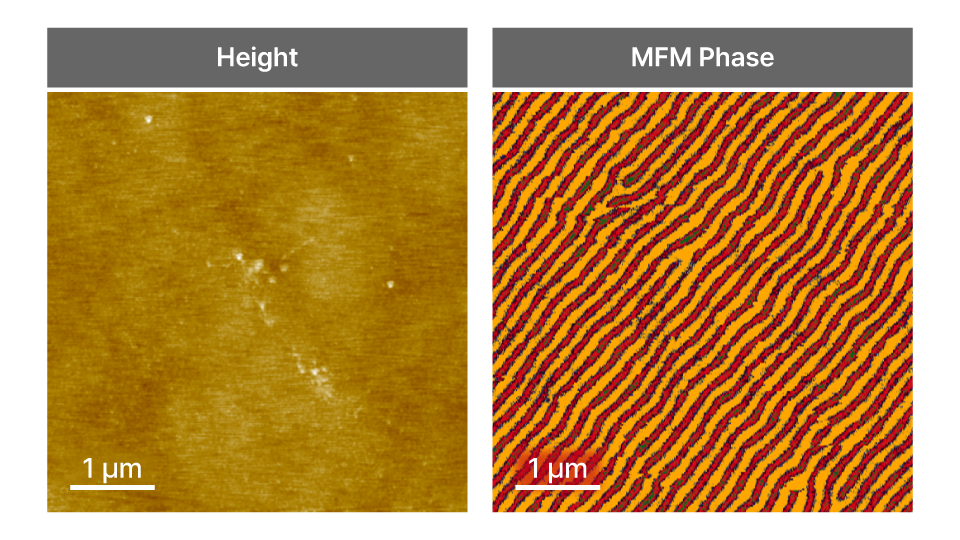

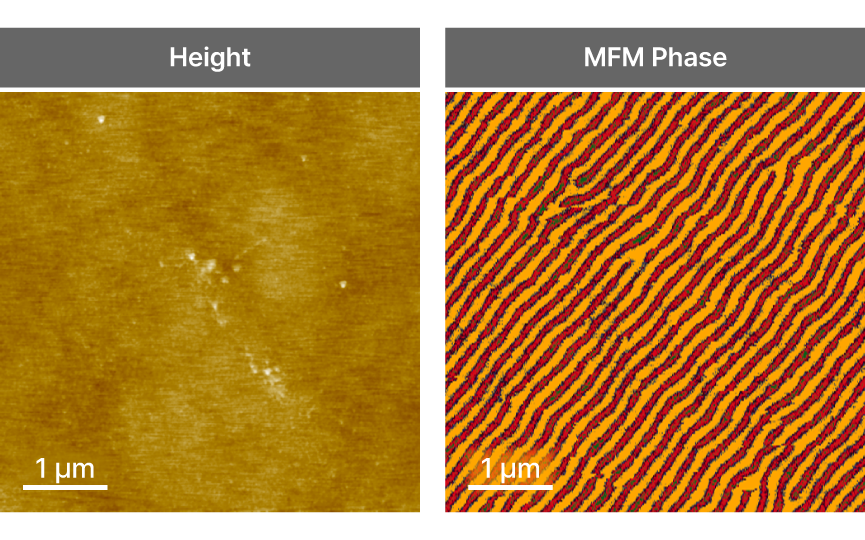

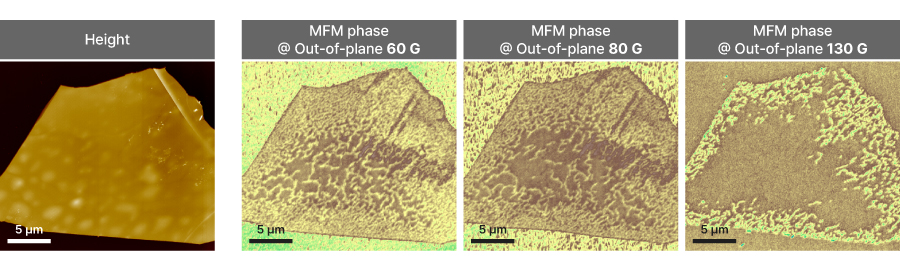

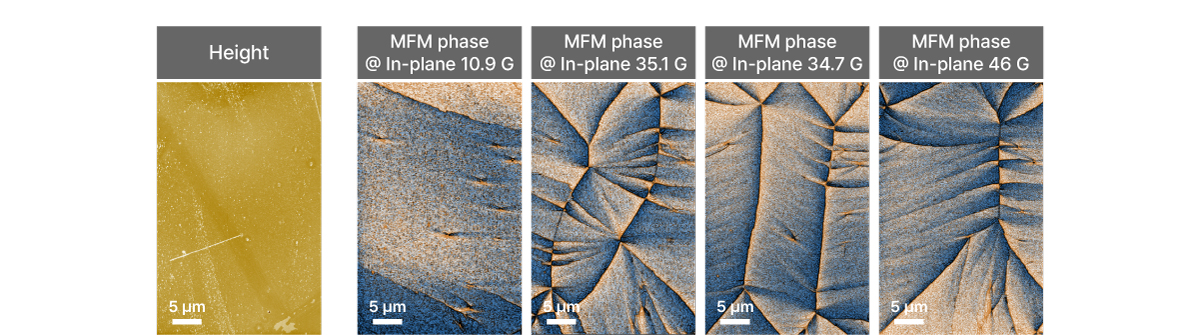

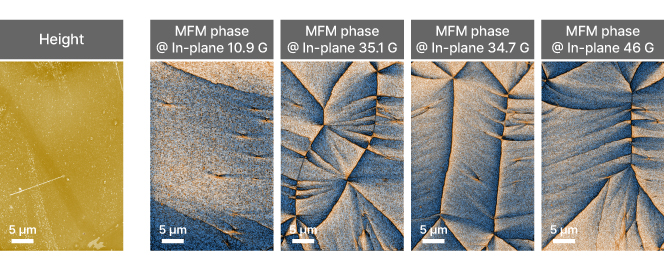

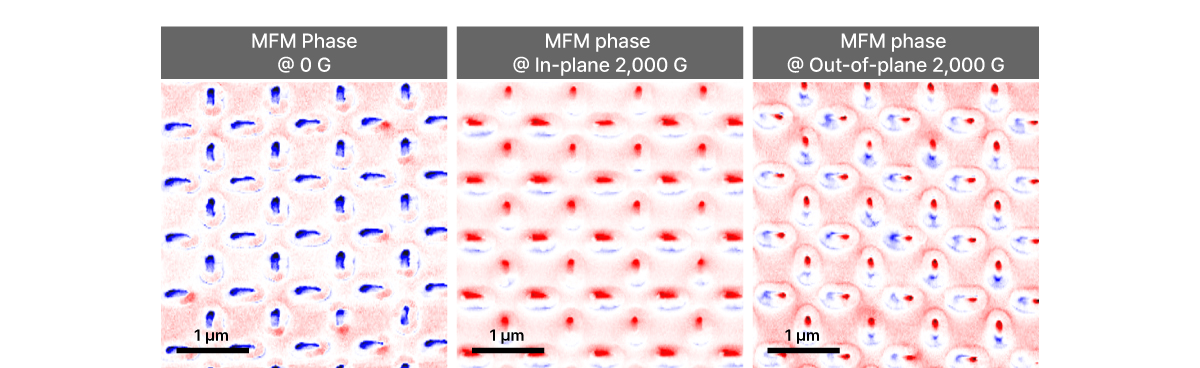

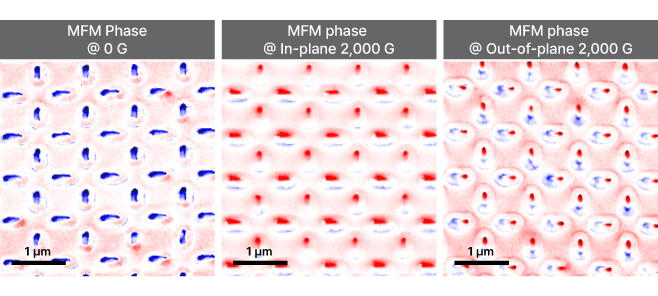

Magnetic Force Microscopy

MFM

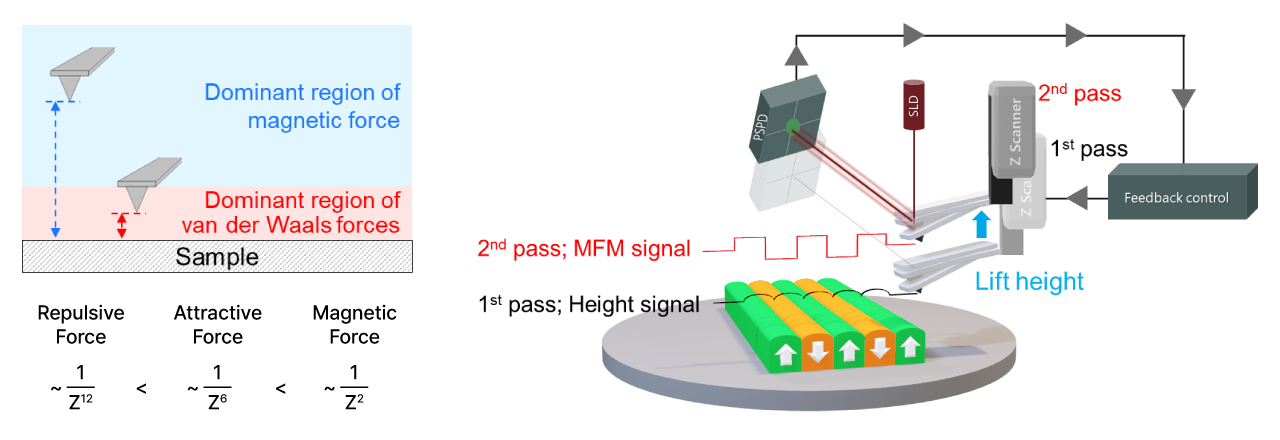

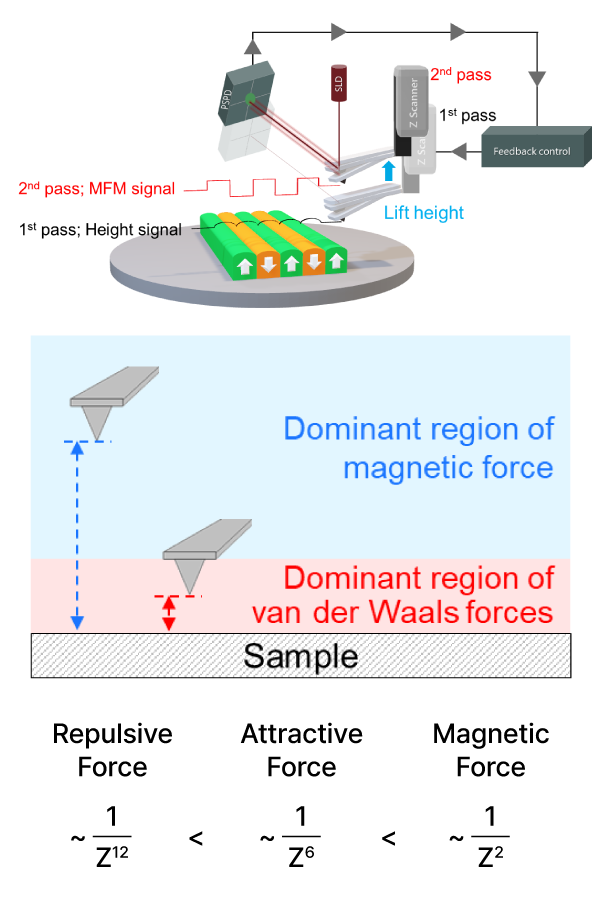

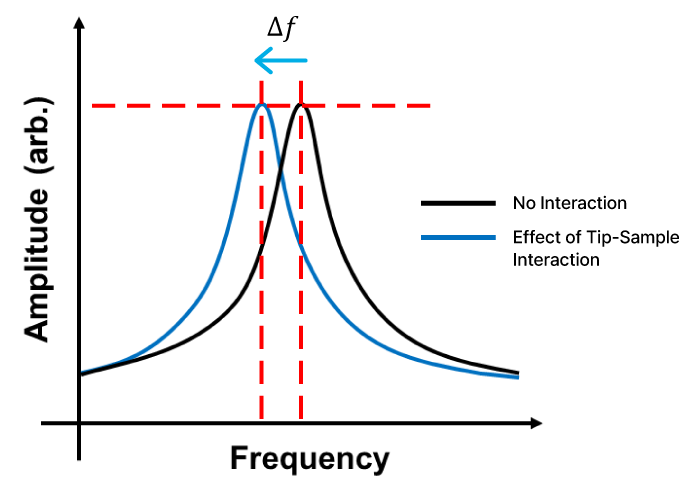

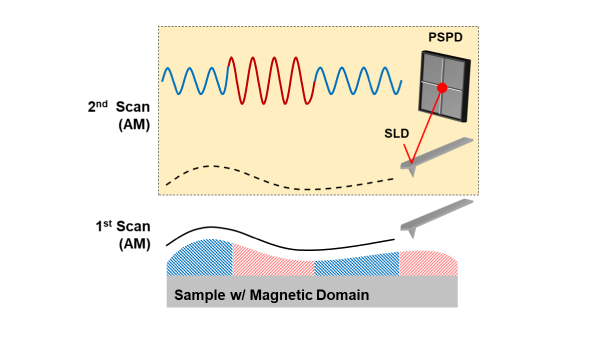

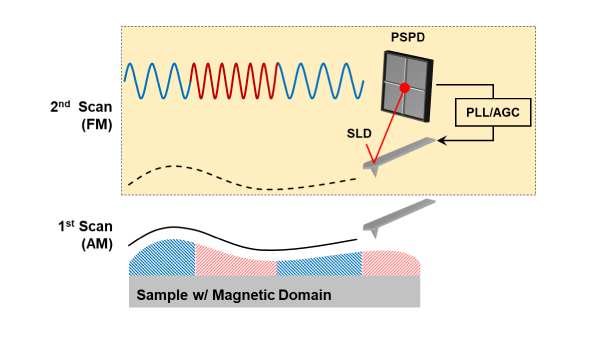

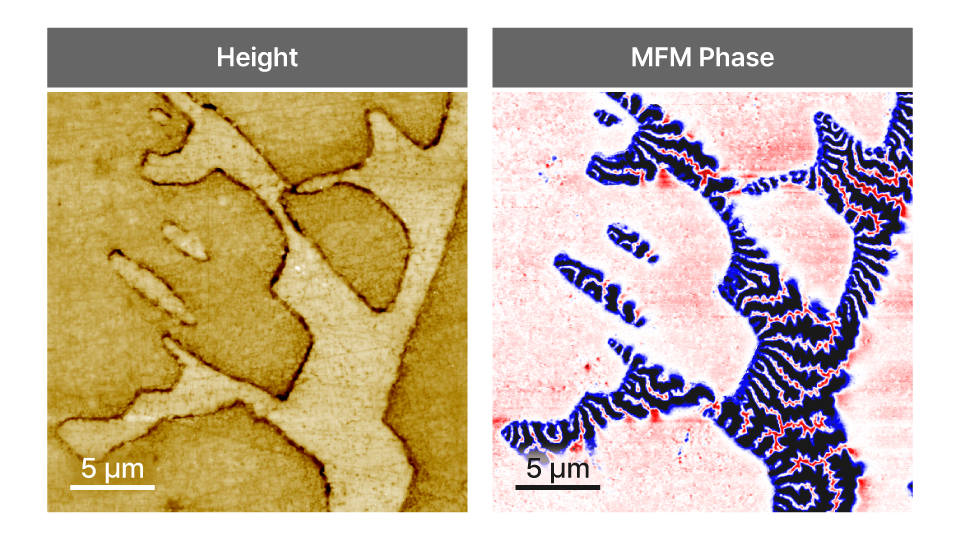

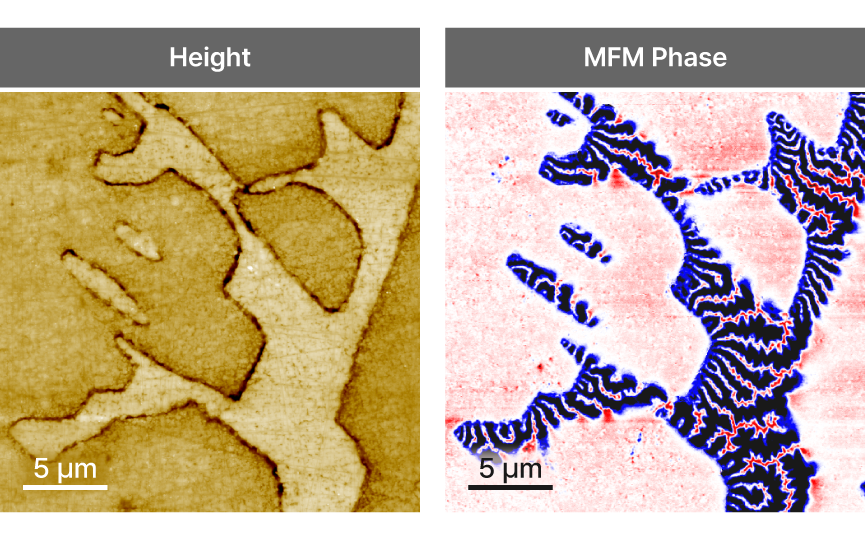

Magnetic properties imaging by sensing magnetic forces between a magnetized

AFM tip oscillating above the sample surface