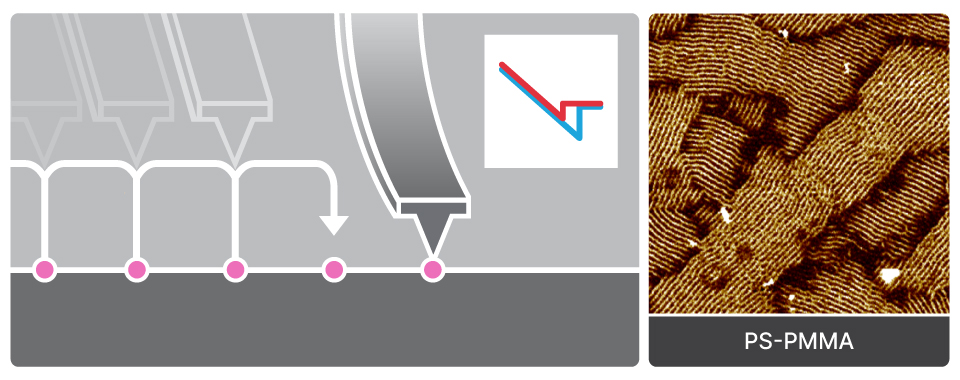

PinPoint

PinPoint™ Nanomechanical

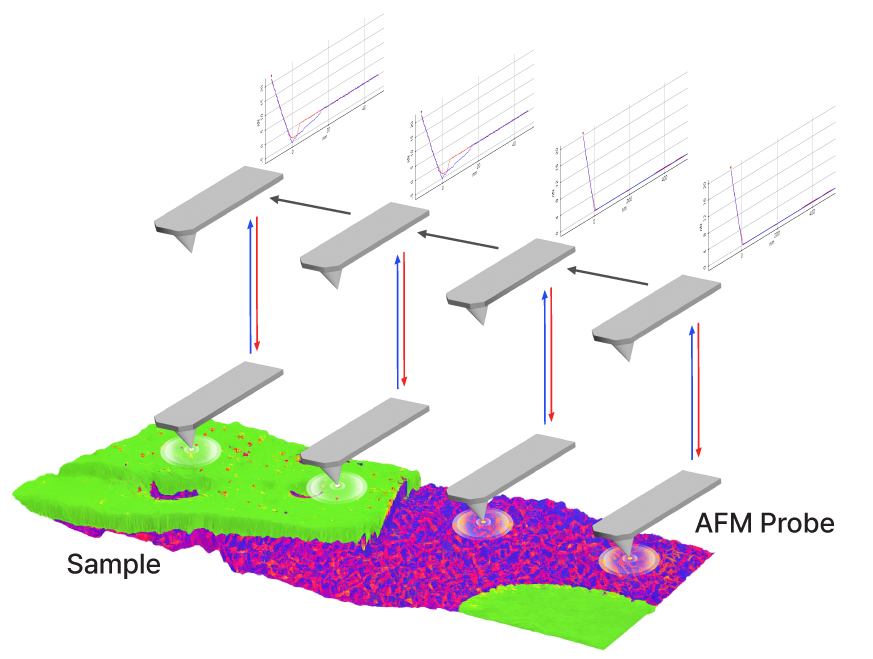

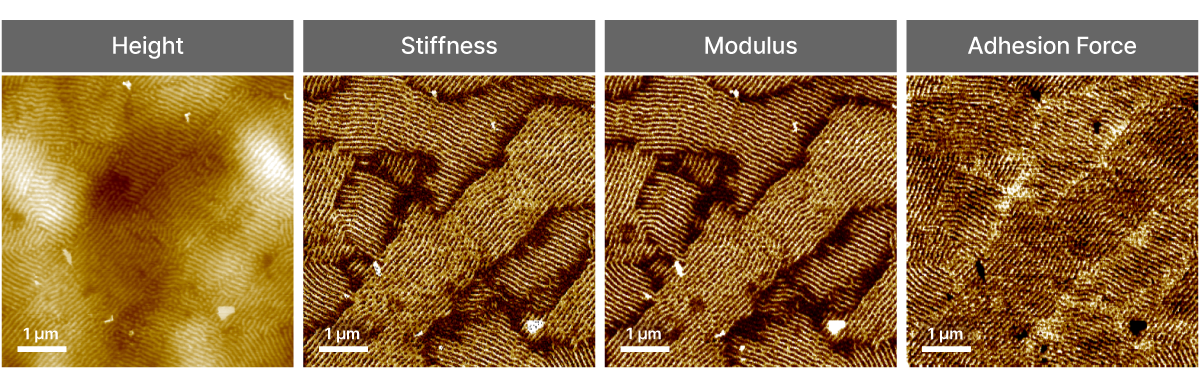

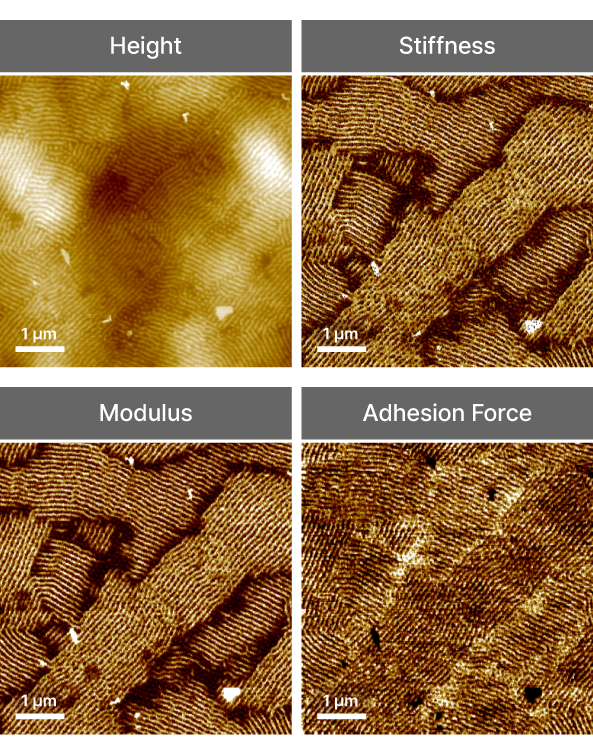

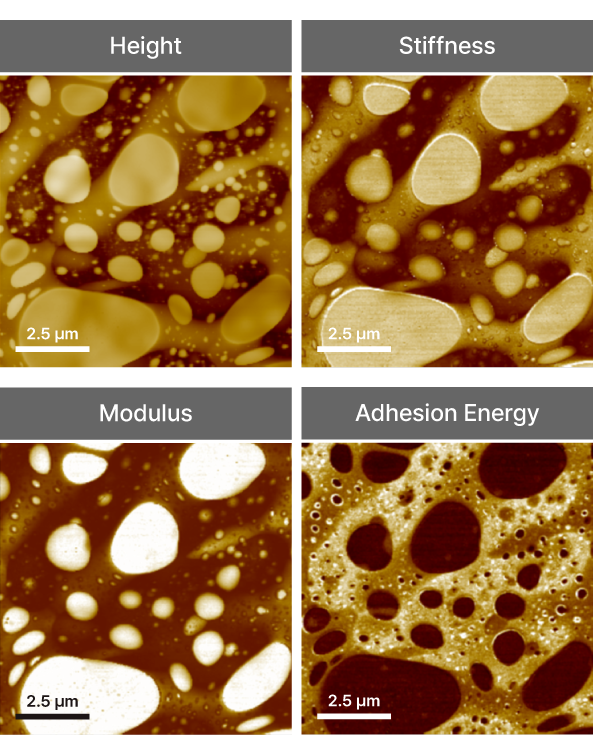

High-speed, force-curve based imaging technique that enables simultaneous mapping of topography and mechanical properties at every pixel