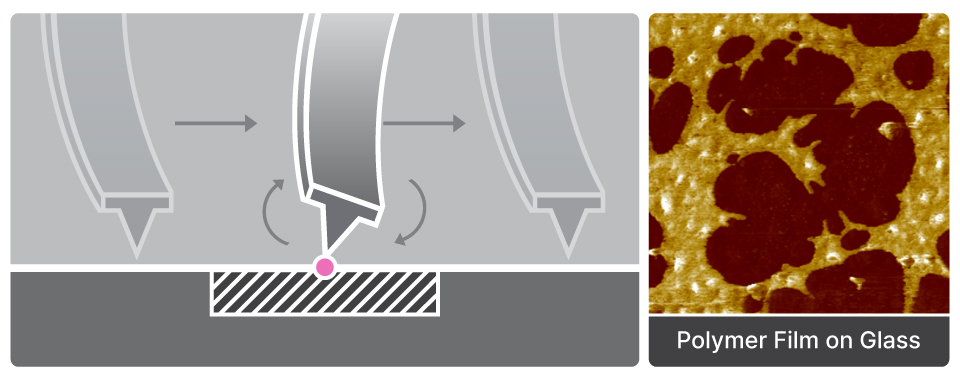

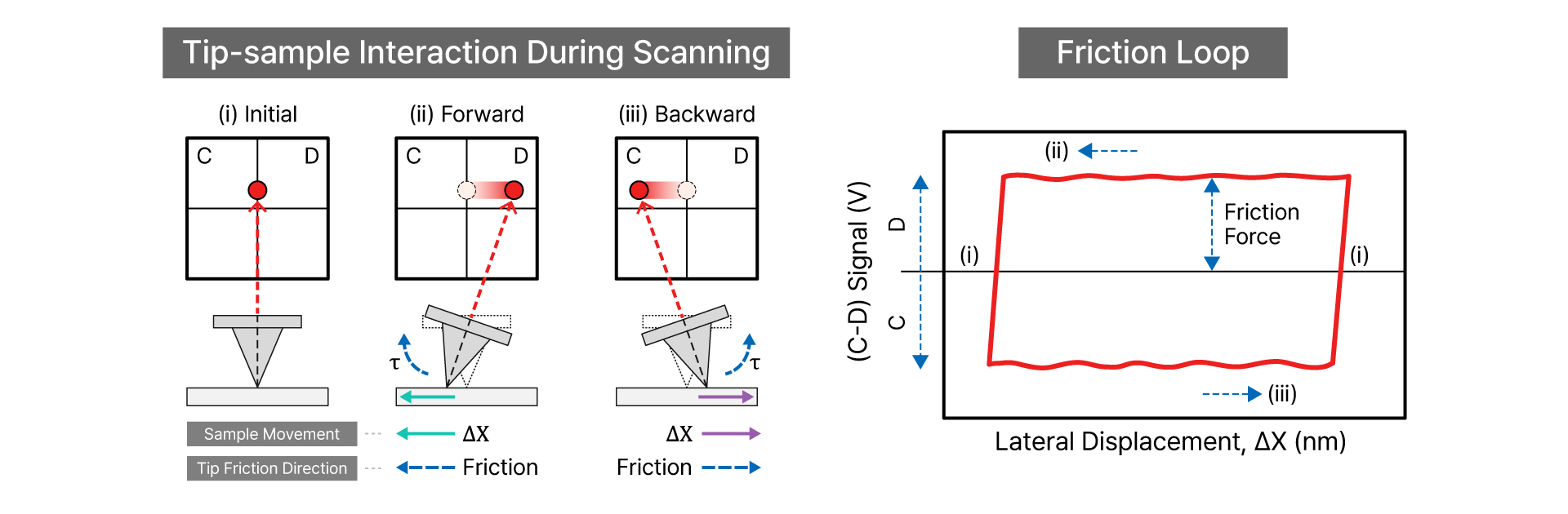

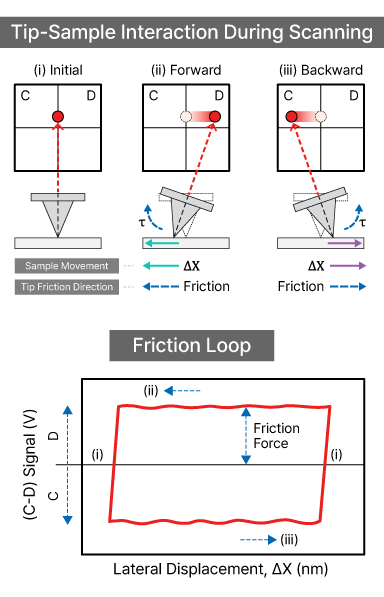

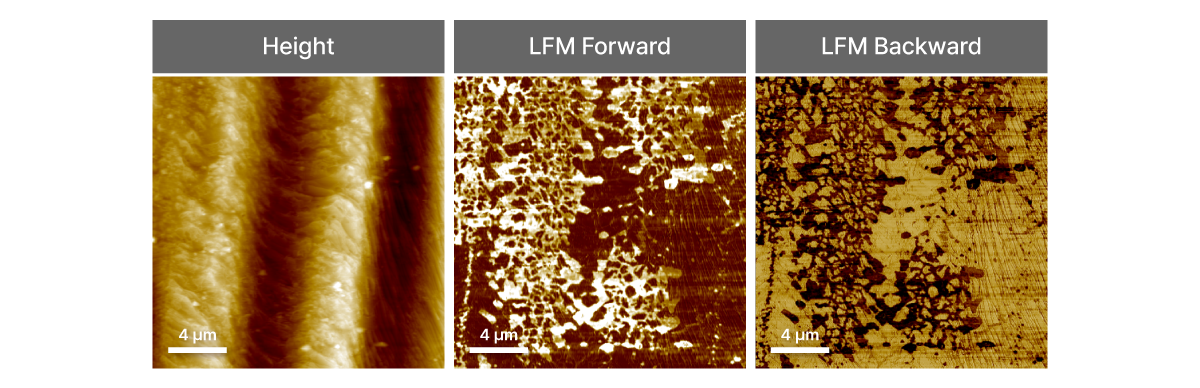

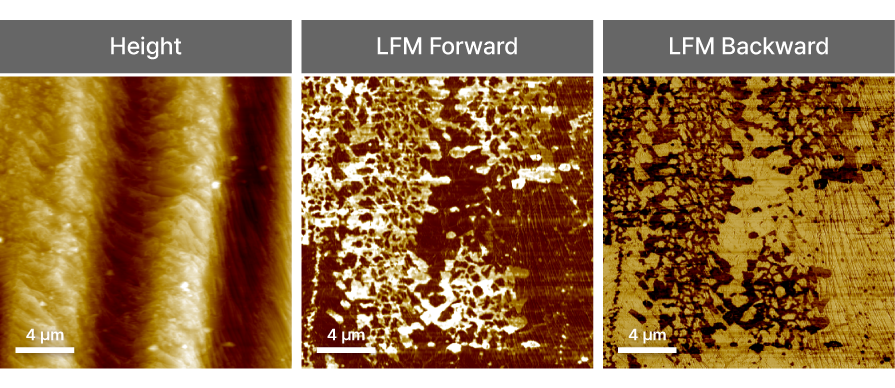

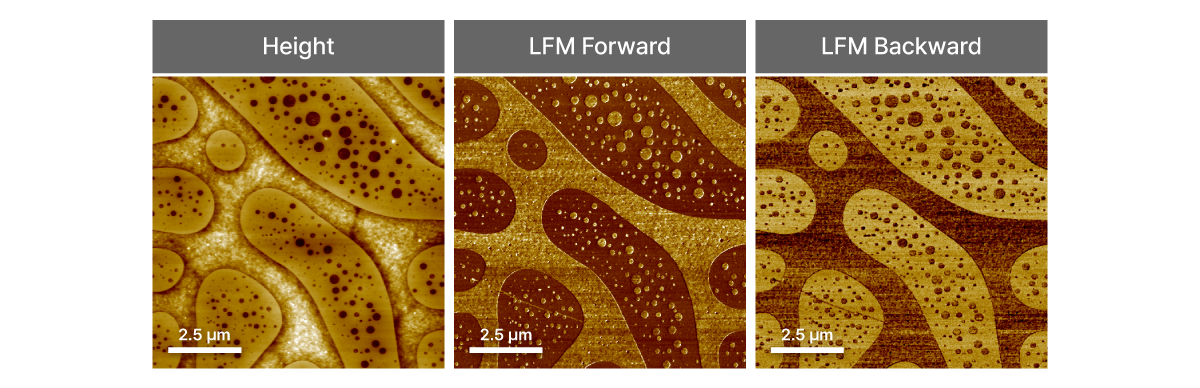

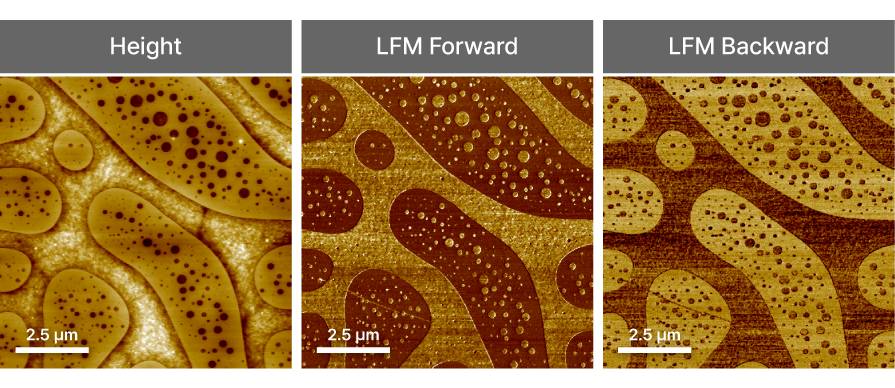

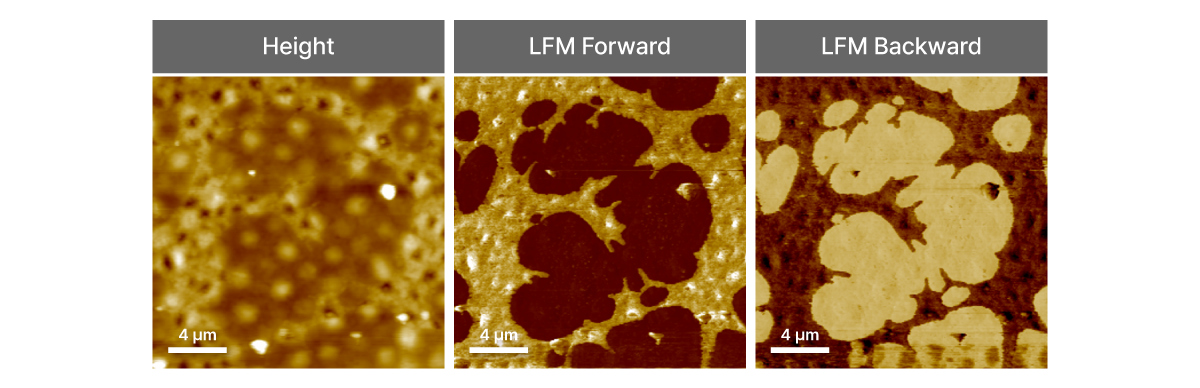

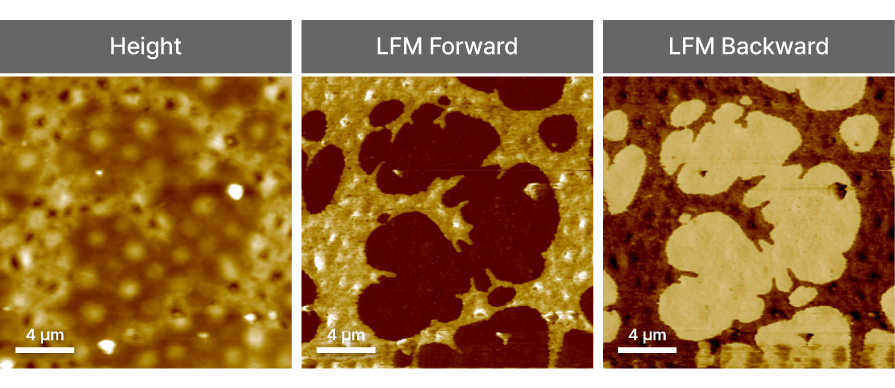

Lateral Force Microscopy

LFM

Analyzing friction and slip behavior through mapping lateral forces across the surface