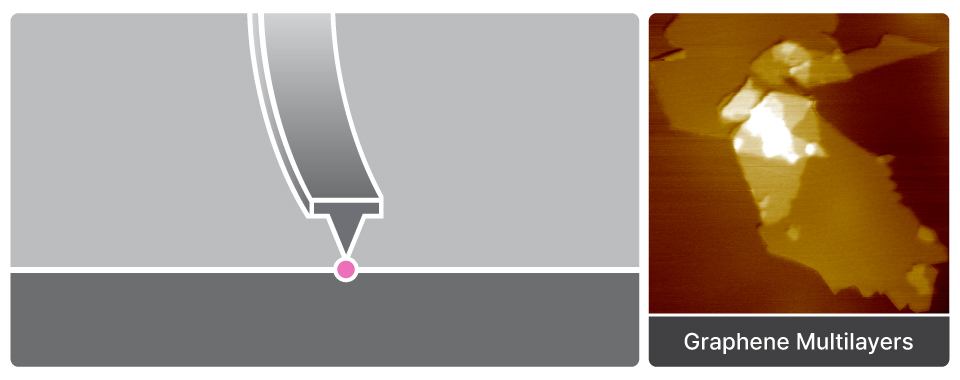

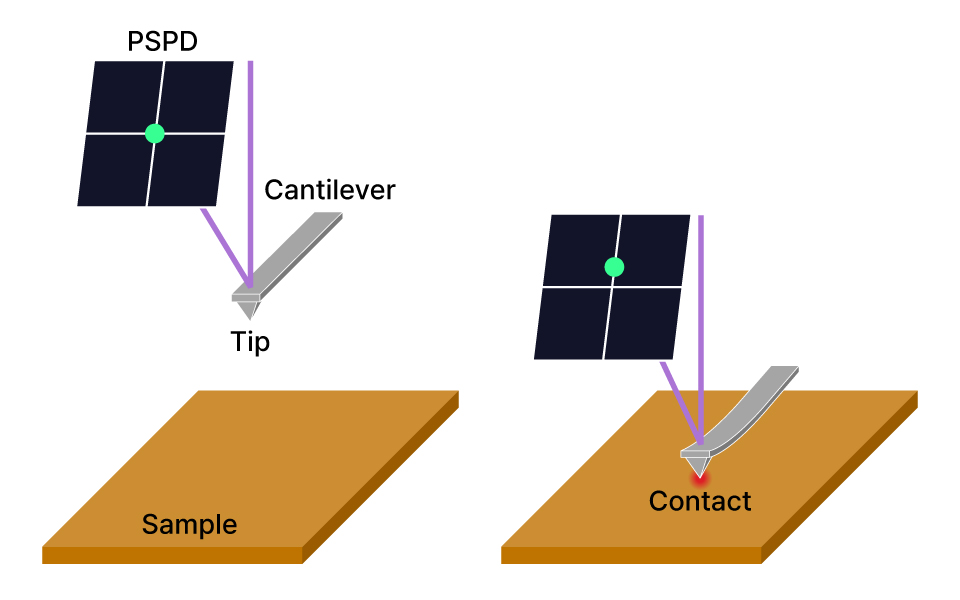

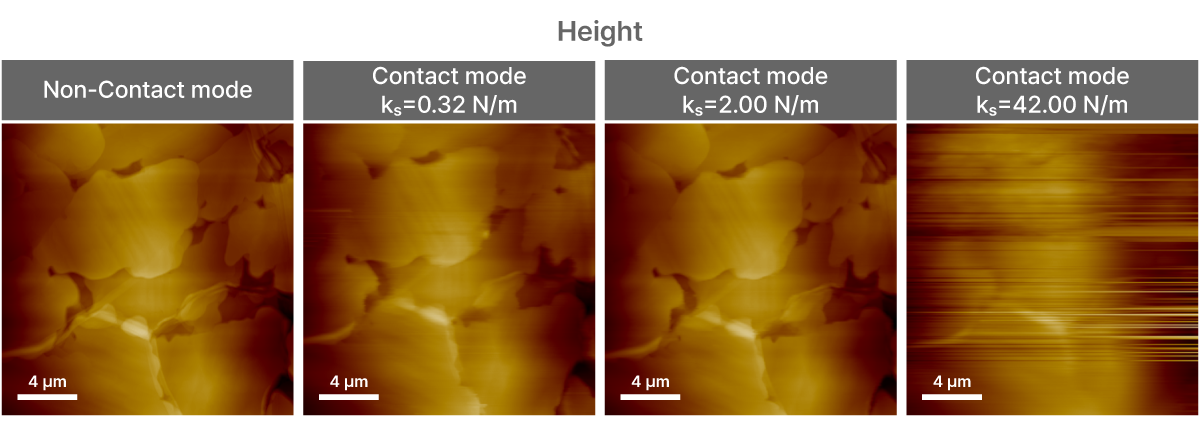

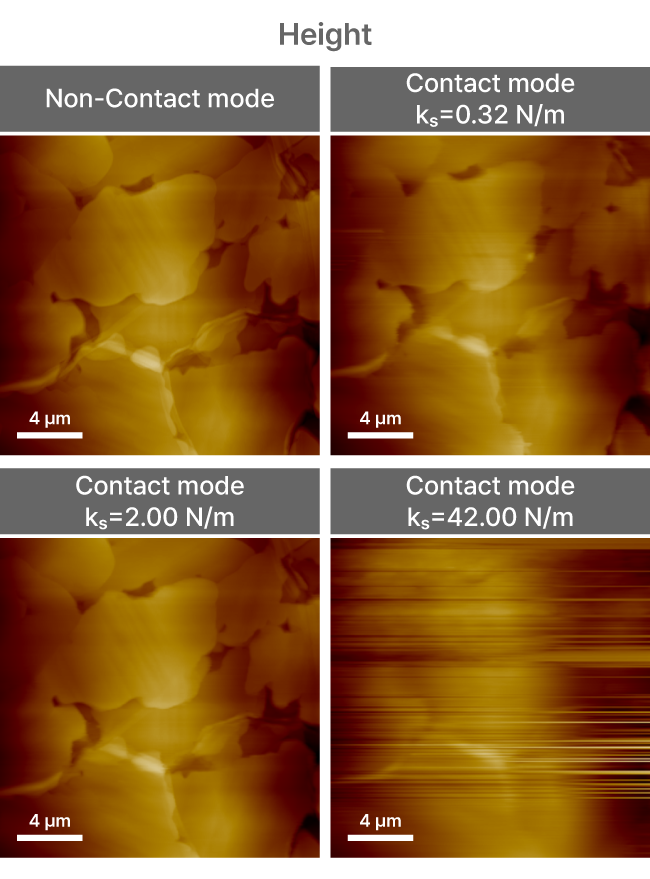

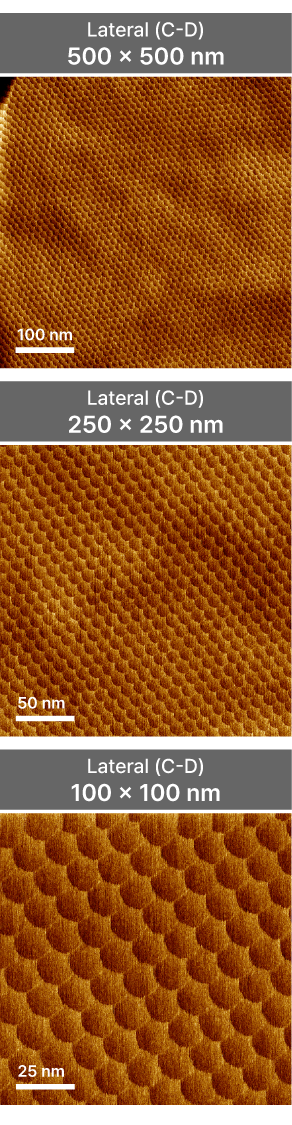

Contact Mode

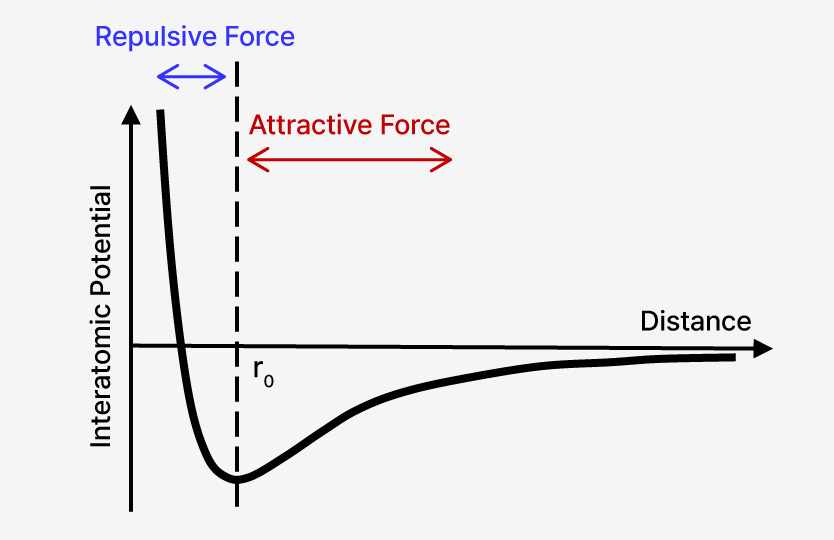

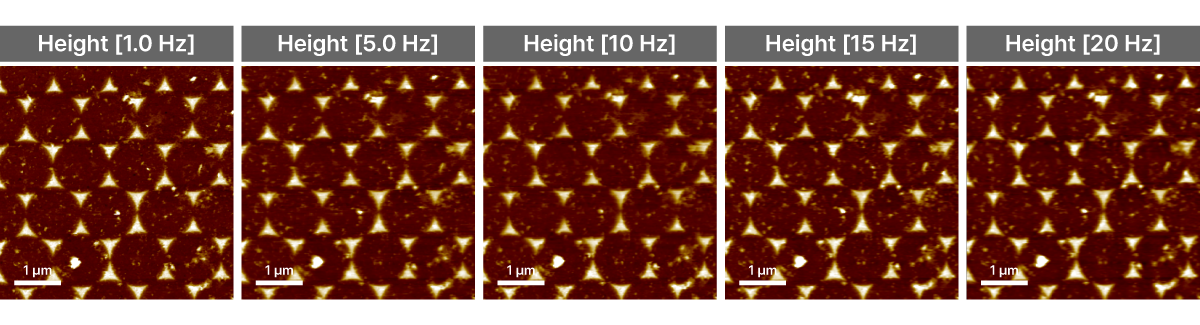

High-sensitivity surface imaging through continuous contact between the AFM tip and sample, providing precise topographical information