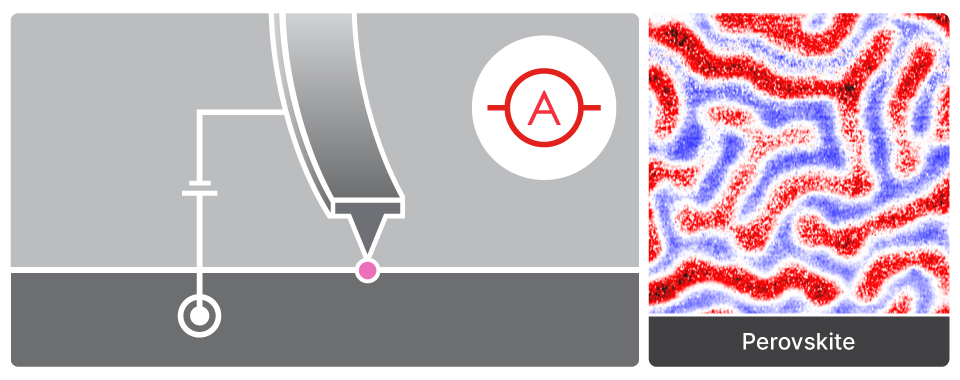

Conductive AFM

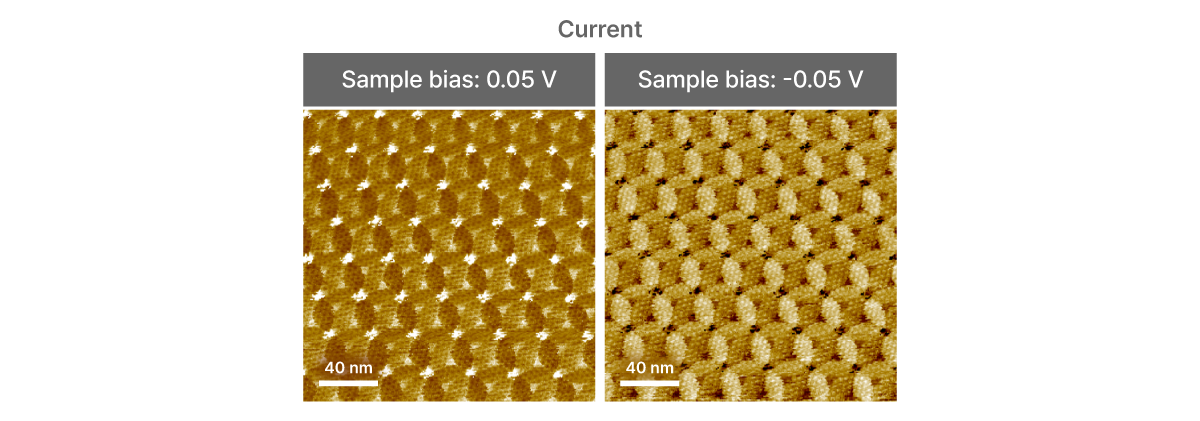

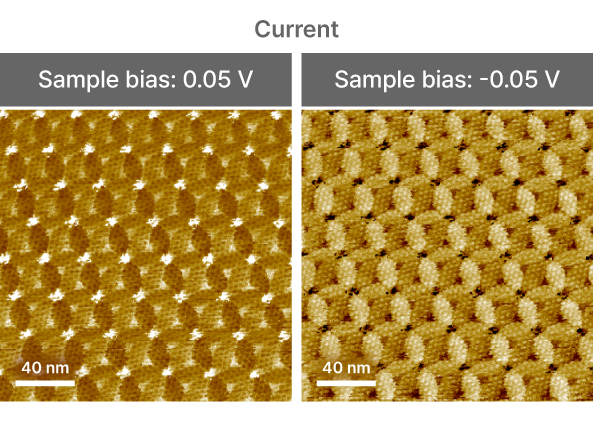

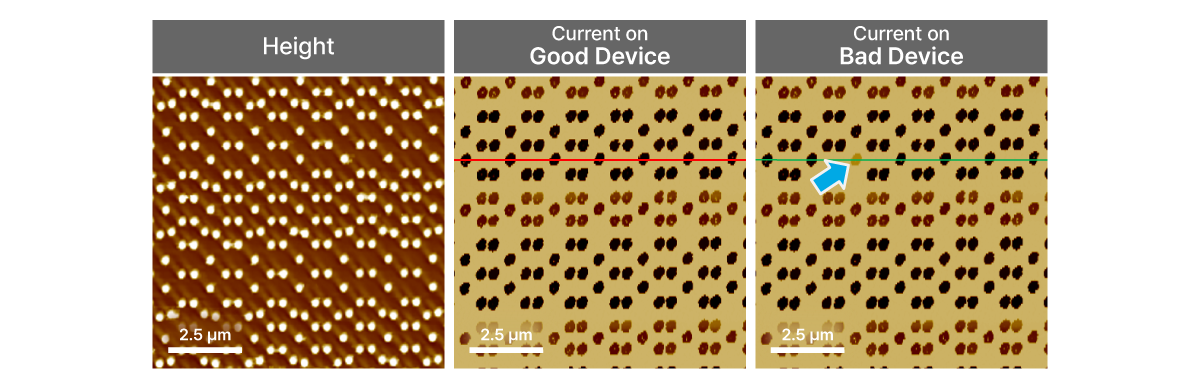

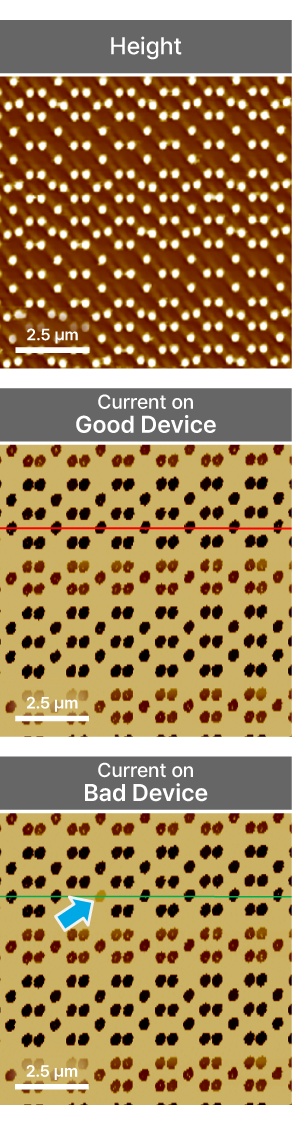

C-AFM

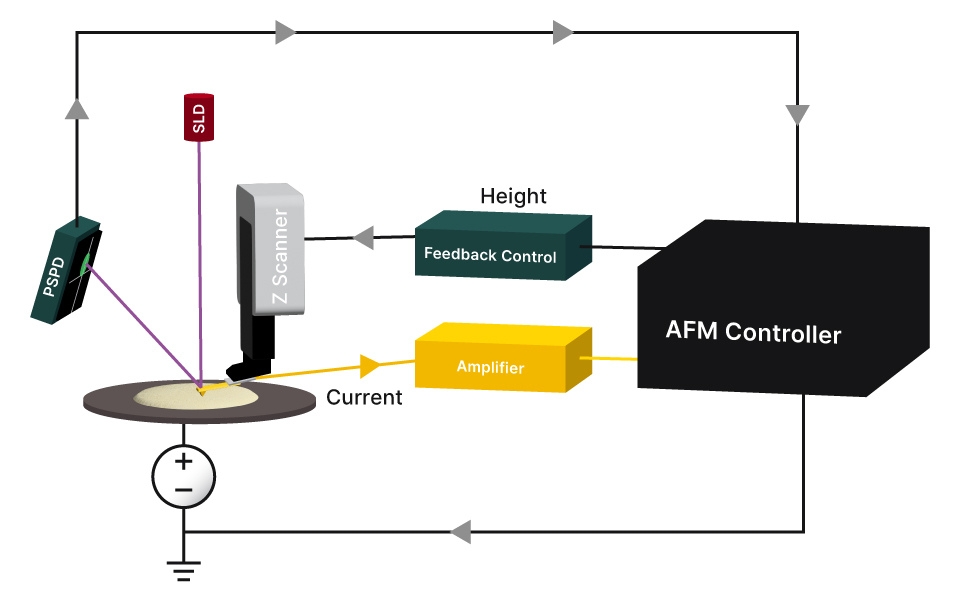

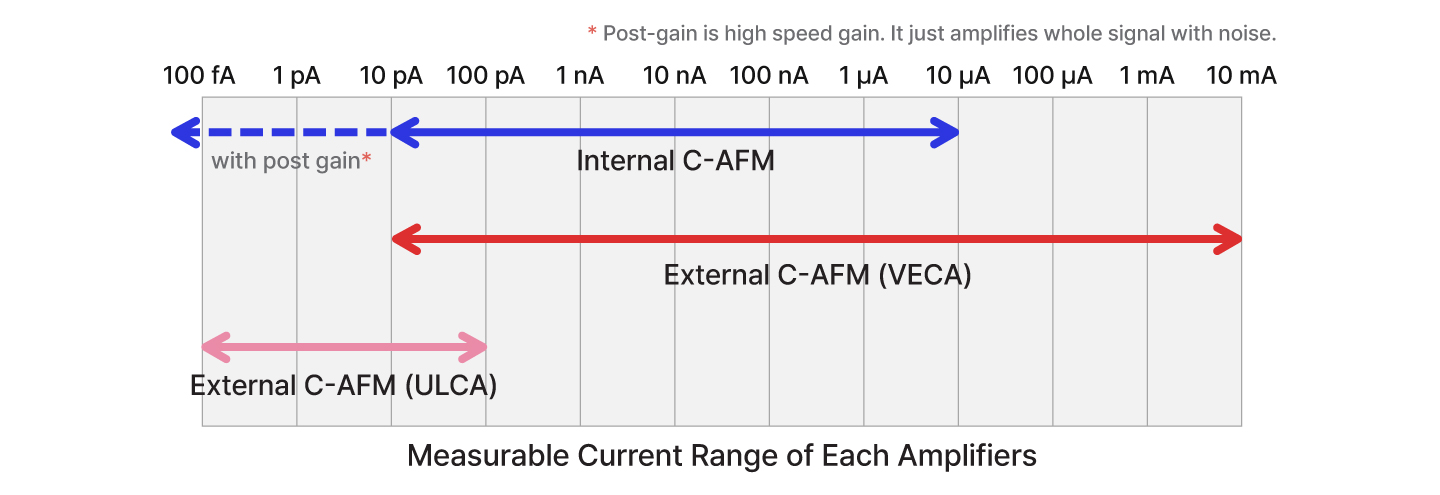

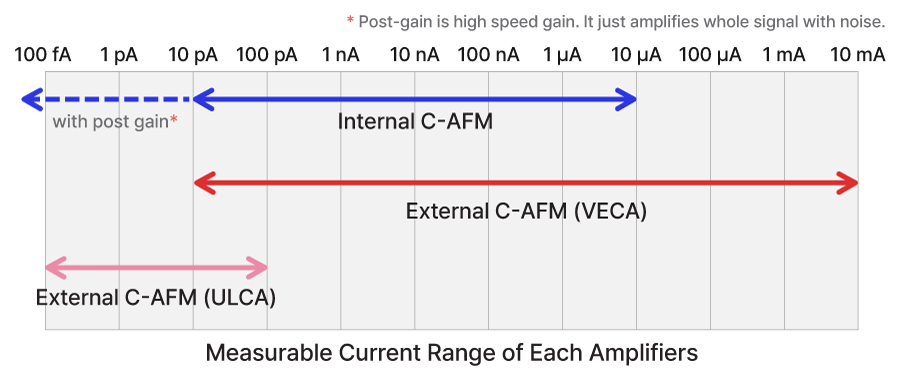

Mapping surface topography and local electrical conductivity via current flow through the conductive AFM tip in contact with the sample