High productivity and powerful features for inline wafer-fab metrology

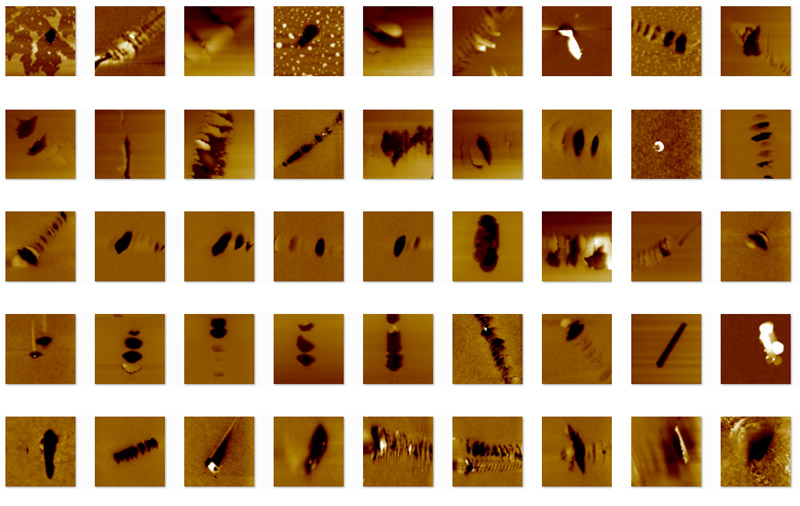

Automatic Defect Review for Bare Wafers and Substrates

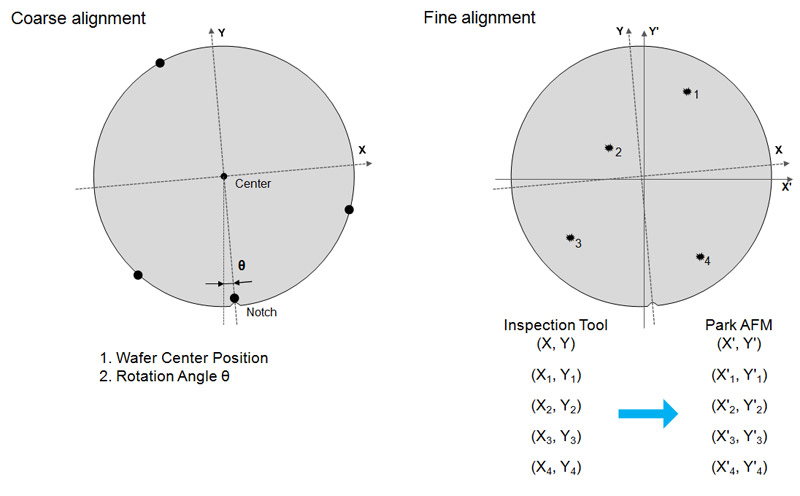

The new 300mm bare wafer ADR provides a fully automated defect review process from transfer and alignment of defect maps to the survey and zoom-in scan imaging of defects that uses a unique remapping process that does not require any reference marker on a sample wafer. Unlike SEM which leaves square-shaped destructive irradiation marks on defect sites after its run, . the AFM-based defect review enables non-destructive 3D imaging of defects as small as a few nanometers. The linkage between a defect inspection tool and the AFM is carried out by advanced coordinate translation with enhanced vision technique. Since it is fully automated, it does not require any separate steps to calibrate the stage of the targeted defect inspection system, increasing throughput by up to 1,000%.

Read More related application

Automatic Transfer and Alignment of Defect Maps with Enhanced Vision

By utilizing Park's proprietary coordinate translation technique, the new Park ADR AFM can accurately transfer the defect maps obtained from a laser-scattering defect inspection tool to a 300mm Park AFM system. This technology does not require any separate step to calibrate the stage of the targeted defect inspection system and allows full automation for high throughput defect imaging.

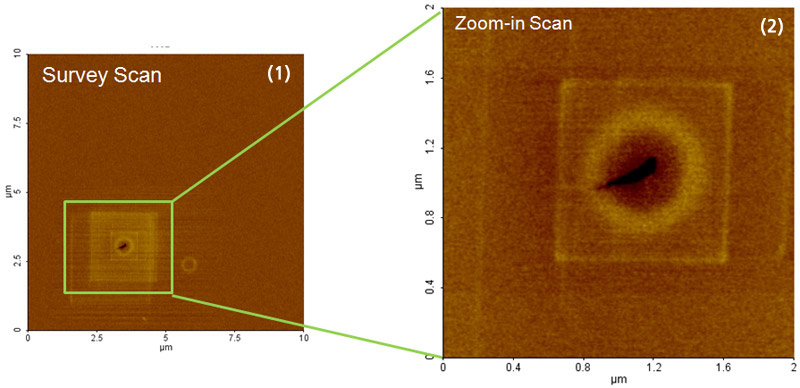

Automated Search & Zoom-in Scan

The defects are imaged in two steps;(1) a survey imaging, either by AFM or enhanced optical vision, to refine the defect location, then (2) a zoom-in AFM scan to obtain a detailed image of the defect, presenting automatic analysis of the defect type and the subsequent defect dimensions. .

Long Range Profiling for CMP Characterization

Planarization is the most important step in the back-end processes where metals and dielectric materials are used. Both local and global uniformity after chemical mechanical polishing (CMP) affect the yield of chip manufacturing significantly. Accurate CMP profiling is a critical metrology necessary to optimize process conditions for best planarity and improve production yield.

Combining Park NX-Wafer with a sliding stage provides a long range profiling capability for CMP metrology. Due to the unique scanner design of Park's automated AFM, the combined system provides very flat profiling and there is no need for complex background subtraction or calibration after each measurement. The Park NX-Wafer enables unprecedented CMP metrology of both local and global planarity measurements including dishing, erosion, and edge-over-erosion (EOE).

Sub-Angstrom Surface Roughness Control

Semiconductor suppliers are developing ultra-flat wafers to address the ever-increasing need for shrinking device dimensions. However, there has never been a metrology tool capable of providing accurate and reliable measurements for the sub-Angstrom roughness of these substrate surfaces. By delivering the industry's lowest noise floor of less than 0.1 Å throughout the wafer area, and combining it with True Non-Contact Mode™, the Park NX-Wafer can make accurate, repeatable, and reproducible sub-Angstrom roughness measurements for the flattest substrates and wafers with minimized tip-to-tip variation. Very accurate and repeatable surface measurements can be obtained even for the long-range waviness measurement of scan sizes up to 100 µm x 100 µm.

High-Throughput Wafer-Fab Inspection and Analysis

• Automatic tip exchange with 99.9% success rate and minimum tact time

• Equipment Front End Module (EFEM) for automatic wafer handling

• Cleanroom compatibility and remote control interface

• Automatic data acquisition and analysis of trench width, depth, and angle measurements

Park NX-Wafer features

Long Range Sliding Stage

The long range profiler is an essential component of Atomic Force Profilometry (AFP) and comes with a dedicated user interface for the automated CMP profiling and analysis.

• 200 mm : 10 mm (optional 25 mm

• 300 mm : 25 mm (optional 10 mm or 50 mm)

100 µm x 100 µm Flexure-Guided XY Scanner with Closed-loop Dual Servo System

The XY scanner consists of symmetrical 2-dimensional flexure and high-force piezoelectric stacks that provide highly orthogonal movement with minimal out-of-plane motion, as well as the high responsiveness essential for precise sample scanning at the nanometer scale. Two symmetric, low-noise position sensors are incorporated on each axis of the XY scanner to retain a high level of scan orthogonality for the largest scan ranges and sample sizes. The secondary sensor corrects and compensates for non-linear and non-planar positional errors caused by a single sensor alone.

15 µm High Speed Z Scanner with Low Noise Position Sensor

The NX-Wafer provides you with unprecedented accuracy in topography height measurement by utilizing its ultra-low noise Z detector instead of the commonly used Z voltage signal that is non-linear in nature. This industry leading low noise Z detector replaces the applied Z voltage as the topography signal. Driven by a high-force piezoelectric stack and guided by a flexure structure, the standard Z scanner has a high resonant frequency of more than 9 kHz (typically 10.5 kHz) and Z-servo speed of more than 48 mm/sec tip velocity enabling more accurate feedback. The maximum Z scan range can be extended from 15 μm to 30 μm with the optional long range Z scanner.

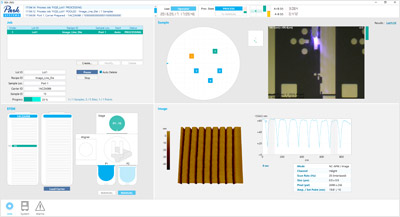

Automatic Measurement Control so you can get accurate scans with less work

The NX-Wafer is equipped with automated software that makes operation nearly effortless. Just select the desired measurement program to get precise multi-site analysis with optimized settings for cantilever tuning, scan rate, gain, and set point parameters.

The NX-Wafer is equipped with automated software that makes operation nearly effortless. Just select the desired measurement program to get precise multi-site analysis with optimized settings for cantilever tuning, scan rate, gain, and set point parameters.

Park's user-friendly software interface gives you the flexibility to create customized operation routines so you can access the full power of the NX-Wafer and get the measurements you need.

Creating new routines is easy. It takes about 10 minutes to make one from scratch, or less than 5 minutes to modify an existing one.

Park NX-Wafer’s automated system features:

• Auto, semi-auto, and manual mode so you have complete control

• Editable measurement method for each automated routine

• Live monitoring of the measurement process

• Automatic analysis of acquired measurement data