Data Analysis in Atomic Force Microscopy Meeting will take place in a virtual format on 10 December 2020. Park Systems is proud to be a sponsor of the conference!

In the Atomic Force Microscopy community there is currently no consensus regarding data analysis and availability. This event aims to discuss different strategies used for data analysis in AFM with the aim of developing a robust and reproducible open strategy for the field, and bring together the AFM community to tackle the lack of consensus across the field regarding data analysis and availability.

Join our technical talk:

"Generating strong AFM images for successful data analysis – Park Systems unique AFM solutions" on Thursday, 10 December

Register: https://www.rms.org.uk/data-analysis-in-atomic-force-microscopy.html

ABSTRACT:

Generating high resolution images has long been the staple of a good AFM system. Nowadays, this is the bare minimum. Nevertheless, despite modern AFM systems focusing more and more on expanding the range of data acquisition capabilities and techniques available with the system including a strong range of nanomechanical and electrical modes, high resolution is still one of the key requirements for research, both academic and industrial, when using an AFM. Both for qualitative and quantitative data acquisition.

There are 4 key stages of development when maximizing the performance of an AFM for data analysis.

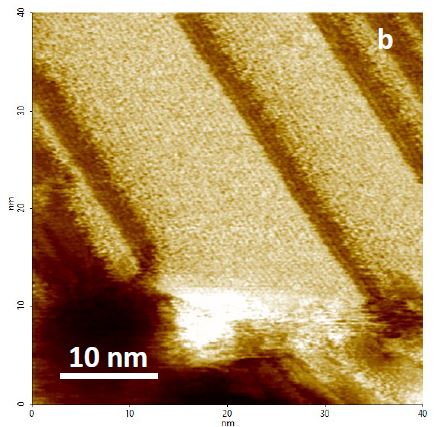

Firstly, the acquisition of high resolution images which are also very stable at the highest resolutions i.e. low noise, to allow for atomic scale data to be extracted.

Secondly, the implementation of advanced modes, such as Parks PinPoint™ mode, to enhance the already existing data acquisition techniques present in most conventional AFMs e.g. nanomechanical, conductive etc… to allow for extraction of the most accurate data possible.

Thirdly, flexibility allowing for as much information about the sample to be extracted without having to prepare additional samples or use more than the necessary characterization techniques to save time, cost and to provide the most efficient system. Both in terms of hardware and software.

Finally, a system that addresses errors. A measurement is only as good as its error and with Parks unique laser alignment design, non-invasiveness and, of course, automation features a variety of well known errors can be reduced or even removed entirely, to make for quantitative data that is both accurate and precise.

The processes discussed above are all implemented by Parks highly experienced Applications Team when performing any measurement however, with Parks unique technology, even a new AFM user has the capabilities to acquire such controllable data whether for research or application purposes.

Image capture: High-resolution AFM image of Teflon surface showing single PTFE molecules.

Wiley Microscopy and Analysis, Dec 2020