AFM and the Semiconductor Industry

Atomic Force Microscopy (AFM) is emerging as an essential tool in the semiconductor industry. As aspect ratios become higher, features become smaller, and requirements for planarity tighten, AFM has begun to replace profilometry both in development and in production, for topographic measurements such as trench and via depths, step height, and micro-planarity measurements. The critical dimensions remain as a major challenge to previous AFMs employed as a semiconductor metrology tool. These AFMs based on tube scanners do not have the sufficient Z-servo speed to properly measure the high aspect ratios of feature sizes. Park Systems, the original pioneer of AFM technology, has changed the concept of AFM by introducing the Park AFM (See Park AFM product datasheets). With its revolutionary Park AFM scan system, the Z-scanner has a ten times higher bandwidth than previous AFMs in the market. Such extraordinary Z-servo performance can afford high speed Z-scanner feedback and enable True Non-Contact AFM. In this application note, the high performance of Z-servo is demonstrated in the critical dimension measurement of high aspect ratio trenches using Park AFM’s True Non-Contact AFM.

High Performance Z-servo

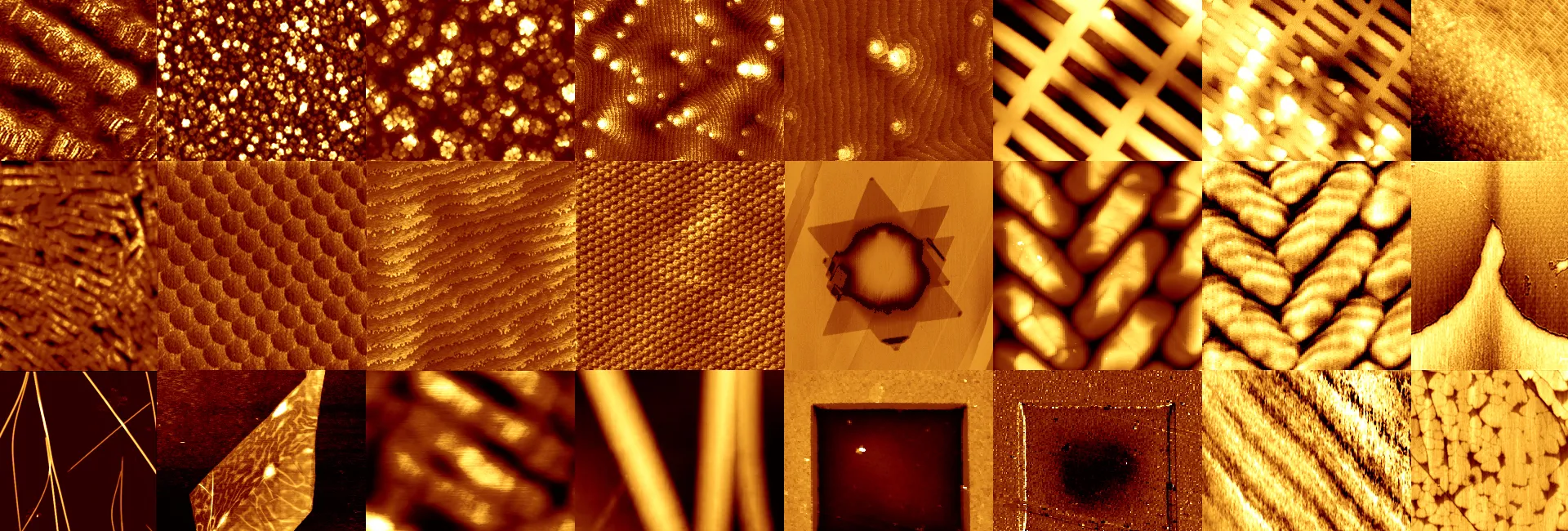

![]()

Figure 1. (a) Park AFM Scan System separates the Z-scanner from the x-y, enabling exceptional Z-servo performance and scan accuracy. (b) Comparison of Z-scanner designs between Park AFM and conventional piezoelectric tube based AFM. The Park AFM’s Z-scanner is a flexure guided high force Z-scanner with Z-servo bandwidth of more than 10 kHz.

The Park AFM scan system is a core feature that gives the Park AFM its competitive edge. Park Systems’ innovative scanner design separates the Z-scanner from the XY, as shown in Figure 1 (a), enabling exceptional Z-servo performance and scan accuracy, unmatched by other AFMs.

The Z-scanner, being separate from the XY-scanner, is designed to have a higher resonant frequency than conventional piezoelectric tube scanners. For this reason, a stacked piezoelectric actuator is used for the Z-scanner, which has a very fast response speed with at least 10 kHz resonant frequency, resulting in a high push-pull force. Since the Z-servo response of the Park AFM scan system is very fast, the probe can precisely follow the steep curvature of a sample without crashing or sticking to the surface, enabling True Non-Contact AFM (see True Non-Contact Park AFM Mode notes). The majority of sample images by the Park AFM is done in True Non-Contact AFM. Therefore, the high performance of Z-servo not only boosts the speed of a profiling scan (consequently the throughput), but also protects the tip, resulting in Park AFM’s ability to acquire clear images for an extended period of time.

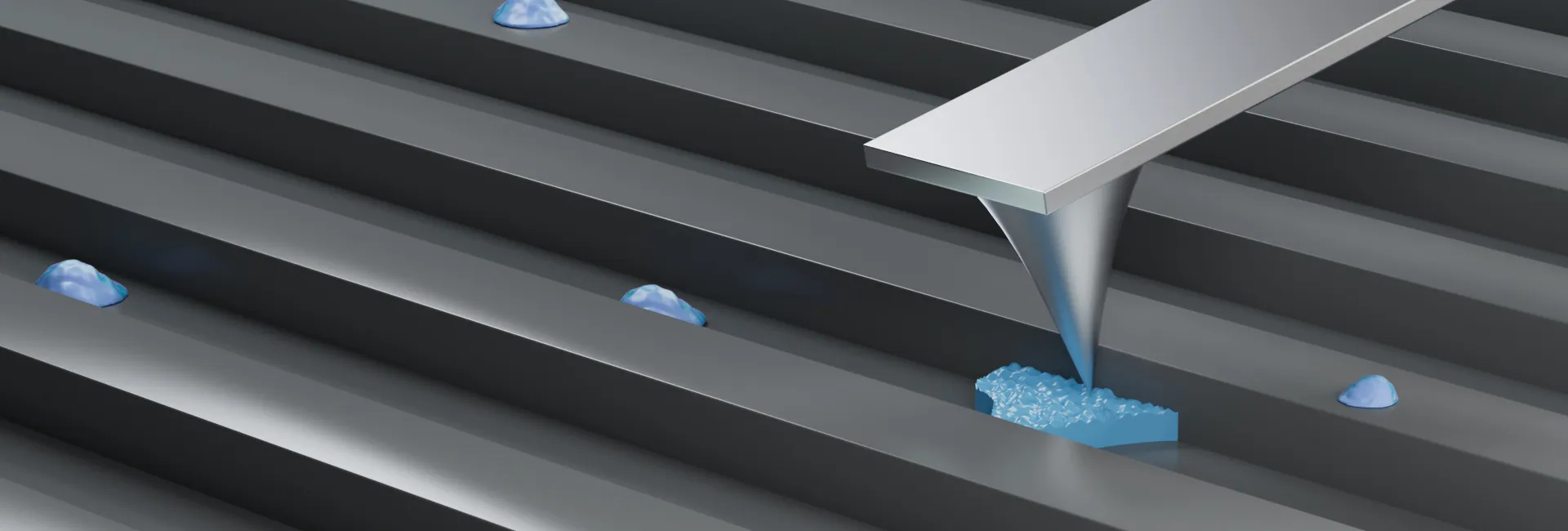

![]()

Figure 2. (a) Image of a shallow trench sample by True Non-Contact mode. (b) SEM image of a high aspect ratio tip before imaging, and (c) SEM image of the same high aspect ratio tip after imaging the same area ten times.

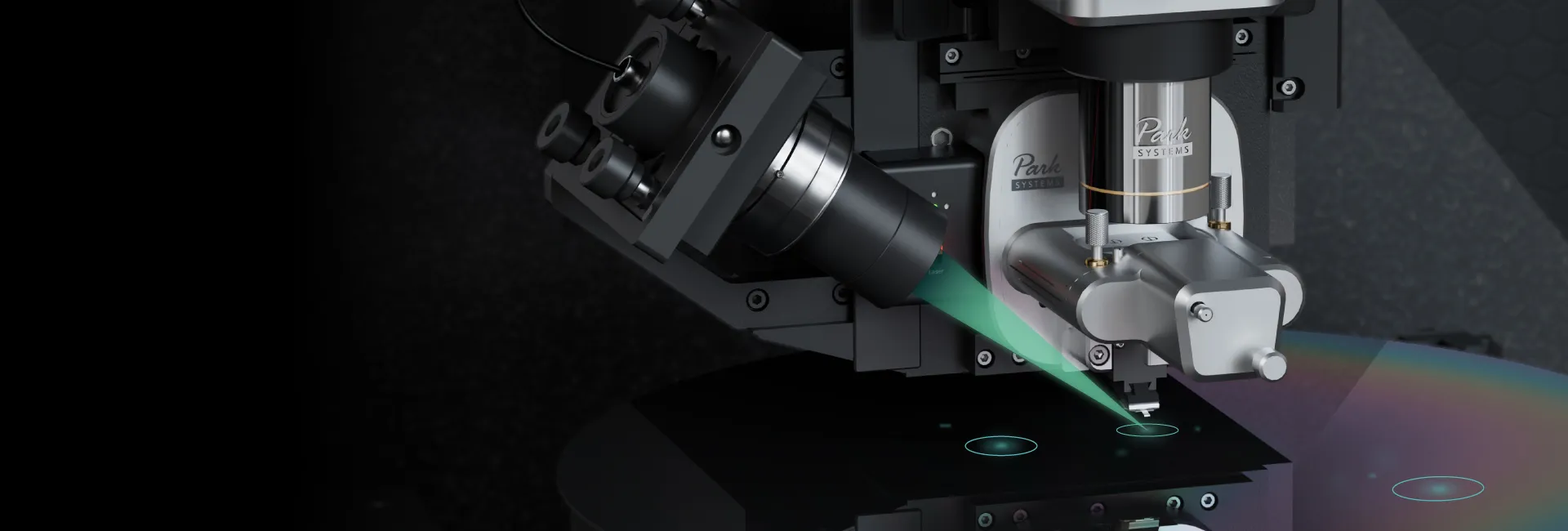

High Aspect Ratio CD Measurement

The high performance of the Z-servo in Park AFM is exemplified in Critical Dimension (CD) Metrology, as shown in Figure 3. The image was taken in True Non-Contact mode using a normal 5:1 high aspect ratio tip. This high aspect ratio sample has a very narrow and deep trench, where the width and the depth are about 160 nm and 550 nm accordingly. Not only are these kinds of images difficult to obtain using a conventional AFM, but they can also rival the performance of a CD SEM without having to cut the sample. It is the high performance of the Z-servo that allows the tip to go down and reach the bottom of the trench and climb up the trench wall instantly without distorting the sample image. Sufficient bottom travel allows the collection of enough data points to effectively represent the bottom of the trench.

![]()

Figure 3. True Non-contact-AFM image of 0.16 μm wide, 0.55 μm deep trenches shown in 1:1 aspect ratio 3D rendering (1.5 × 1.5 μm).

What is more powerful in this image is the accurate detection and imaging of the sidewall and trench edges. In Park AFM’s True Non-Contact mode, the probe senses not only at the end of the probe, but also in every direction of the probe. As the probe approaches a side wall, it senses the wall at the side of the probe. The resonance frequency will change and the z-scanner will instantly pull up until it reaches equilibrium. This provides the semiconductor industry customers with an ultimate solution for CD metrology, including the side wall angle measurements. On the contrary, tapping mode’s interaction is limited to the bottom of the tip and the top surface of a sample, and the feedback measures the amplitude change of the tip bouncing off the sample. Therefore, when it comes to the side of a wall, the tapping mode feedback does not comprehend the lateral force causing the tip to break.

Conclusion

With its revolutionary Park AFM scan system, the Park AFM’s Z-scanner has ten times the bandwidth than that of other AFMs in the market. The unprecedented high performance of Park AFM’s Z-servo allows for True Non-Contact AFM that can accurately trace high aspect ratio features, and obtain accurate detection and imaging of the sidewall and trench edges.