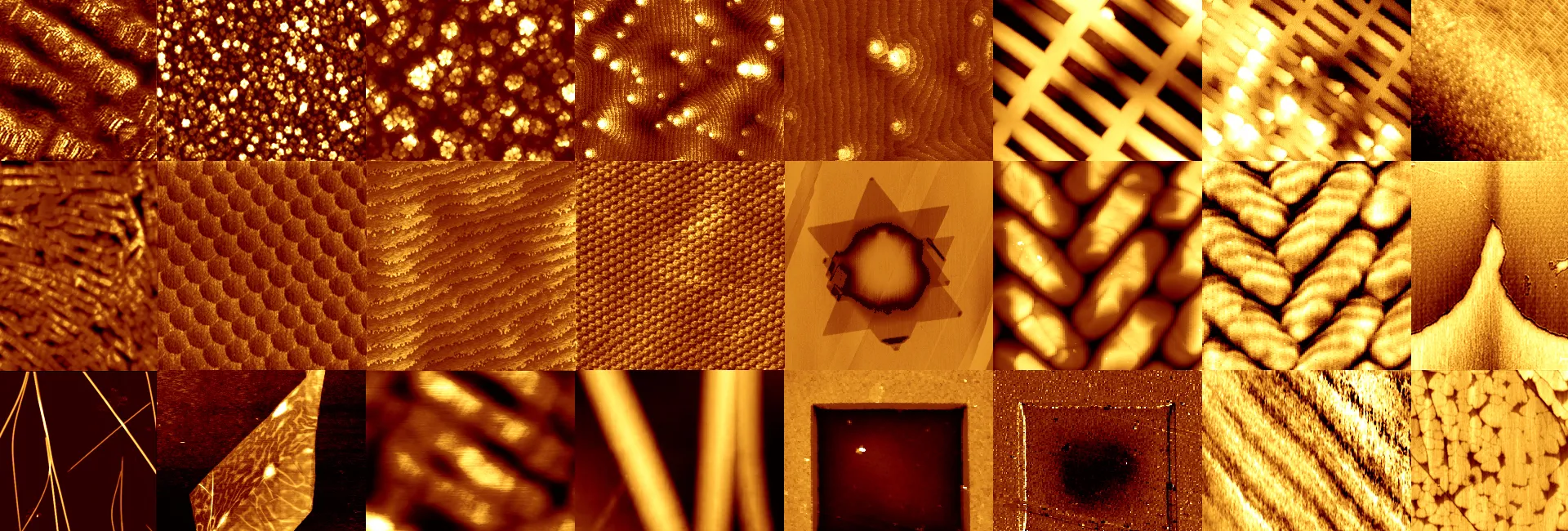

Emerging Trends of Nanotechnology

Read the Park systems' Technical Articles about AFM to understand recent developments

AFM Experts provides you Online Courses, Webinar, Live Demos and Educational Videos from AFM Experts

Park Systems aims to support the next generation of Trail Blazers in Nanoscience by encouraging young researchers to share and discuss their research

Latest Park News

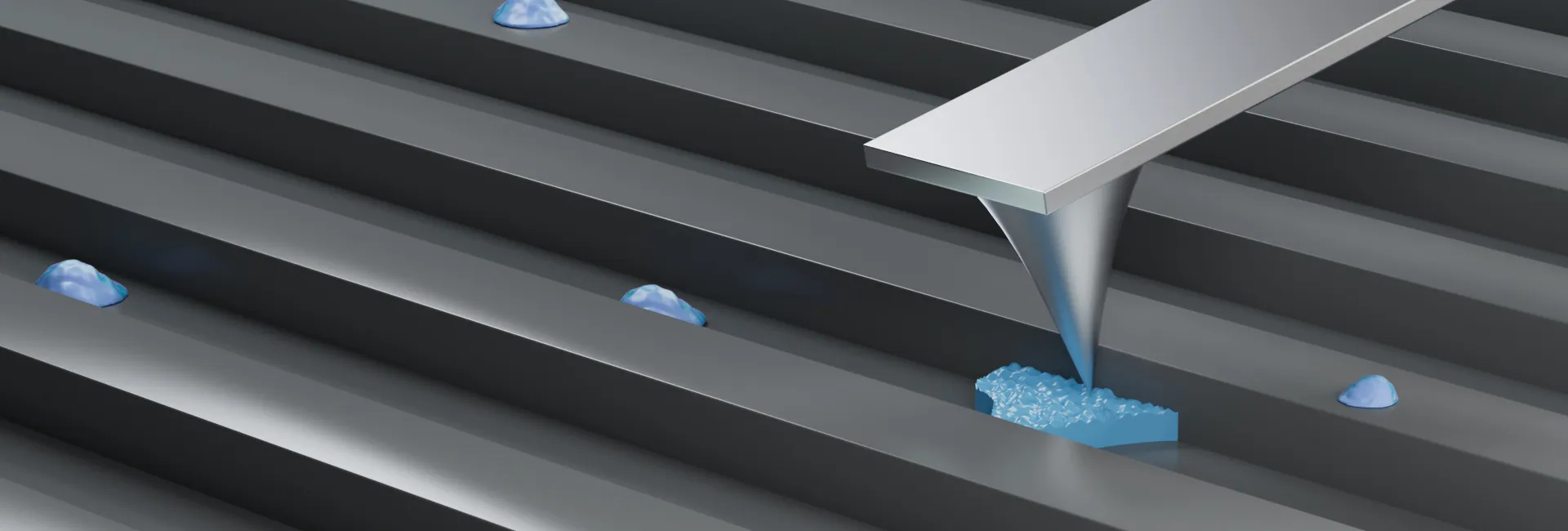

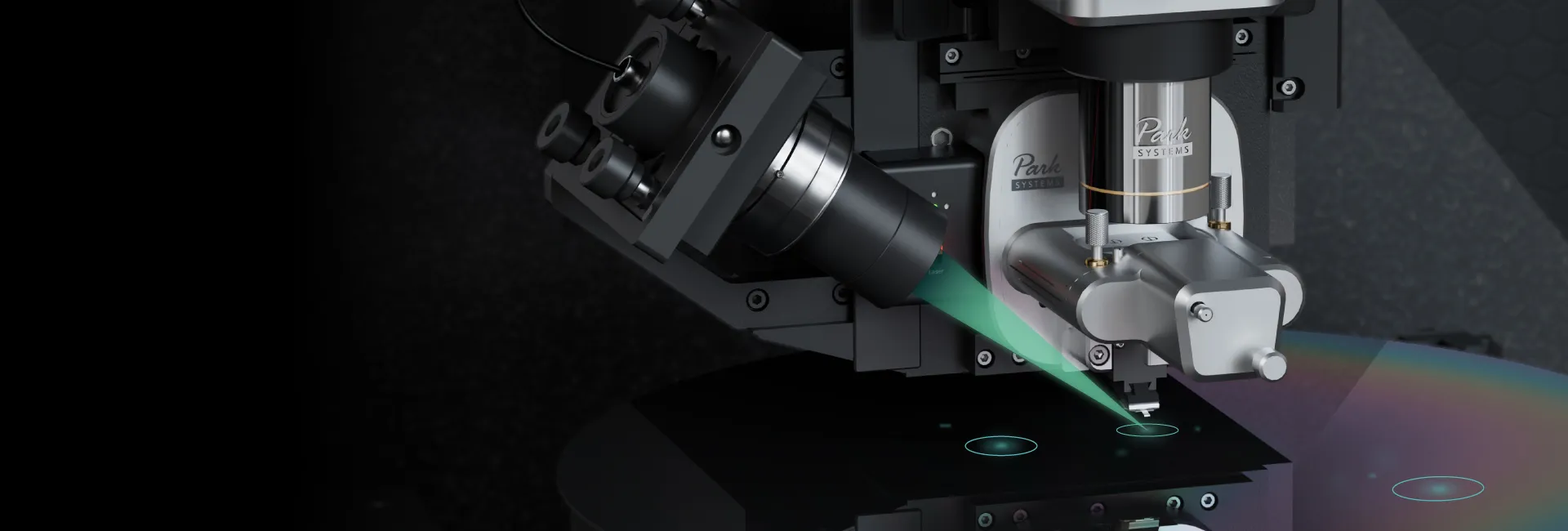

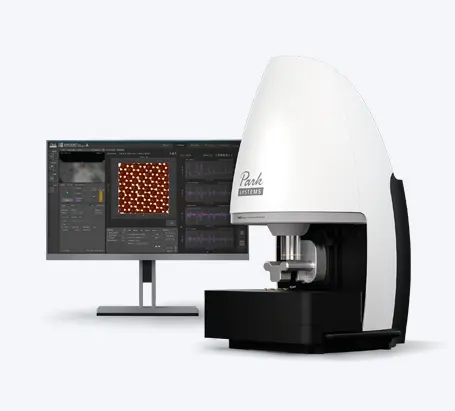

Explore Park Products

Experience our product's high-quality, precise, and long life backed by our worldwide service network. We are strongly committed to maintaining the quality of our products, making us a trustworthy choice for all your repair and maintenance needs.

We await your inquiry and will arrange for you to speak with a specialist today to explore tailored solutions for your research needs. Please fill out the form now, and we will promptly get in touch with you.

Don't miss out on new product announcements, the latest tech insights, special events, and more. Subscribe now to receive regular updates straight to your inbox!