Mina Hong, Gerald Pascual, Byong Kim, and Keibock Lee

Technical Marketing & Applications, Park Systems Corporation

Introduction

The Atomic Force Microscopy has provided those in research and industry with high resolution nanoscale measurements and imaging, but has long been limited by its relatively slow imaging speed. For certain applications such as crystal nucleation and growth, materials transportation and protein self-assembly process [1-3], it is important to keep track of the topography changes and particle transportation. For such studies, an AFM needs to be able to image as fast as possible without overly sacrificing the data accuracy and repeatability required to reproduce the work. In order to meet this challenge, engineers from Park Systems have pushed themselves to improve their existing AFM systems to scan at an increased frequency without loss of resolution and accuracy and the need for any additional costly setup.

Today, with Park's NX series of AFM systems and high frequency cantilevers, one can generate AFM images at the expected high resolution while maintaining a significantly increased scan speed compared to legacy systems. All Park NX series AFMs are built for fast Z scanner feedback speed and optimized Z servo control so only an ultra-high frequency cantilever is all that is needed to carry out high-speed AFM imaging. Park's Fast Imaging is the most optimized solution to the need for expedited AFM image generation. This enables the researcher to perform fast and accurate imaging of sample surfaces covering a wide spectrum of feature heights, ranging from single nanometers to tens of nanometers.

Experiments

In order to determine whether Park Systems's technology delivers superior scan speed while maintaining high resolution performance, Park NX10 AFM was used to perform a fast imaging operation with ultra-short cantilevers (USC) supplied by NanoWorld. USC has a spring constant of 3 N/m and a resonance frequency of 2 MHz. Three commercial products were imaged to test the ease of use and accuracy of the AFM's fast imaging capability. All experiments were run under non-contact mode using Park SmartScan AFM operation software.

The first sample imaged was pentacene film. Pentacene is a polycyclic aromatic hydrocarbon consisting of five linearly-fused benzene rings. The rings are connected to form a structure that has surface height differences of roughly 10 nanometers. It is a highly conjugated compound that can be used as an organic semiconductor. The second sample that was run was a triangular aluminum production pattern. The third sample tested was Celgard, a material used as a separator and filtration membrane in porous lithium ion batteries as well as in several medical applications. The surface of Celgard has a high variation of feature heights, on the order of tens of nanometers. All samples were imaged with a speed increase from 1 Hz to 10 Hz to determine whether high resolution imaging could be maintained while capturing the topographic changes and particle transformation of the samples.

RESULTS & DISCUSSIONS

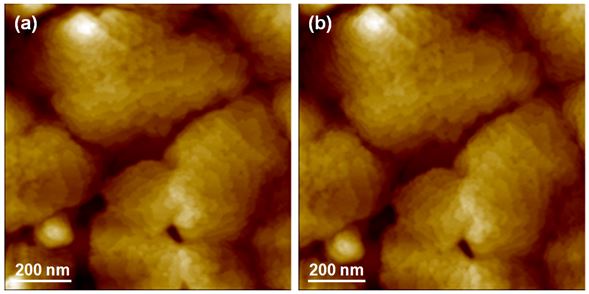

The experiment clearly showed that Park NX10 AFM provided high resolution, high productivity, and high performance at increased scan rates. Figure 1 clearly exhibits the pentacene sample surface features such as holes (defects) and the monolayer structures. With the scanning speed increased from 1 Hz (Figure 1a) to 10 Hz (Figure 1b), there is no obvious difference between these observed features. We believe with a scanning speed of 10 Hz, the changes in the pentacene's surface topography can be well tracked in environments that promote real growth or dissolution.

Figure 1. images of pentacene film imaged at (a) 1 Hz and (b) 10 Hz.

Figure 1. images of pentacene film imaged at (a) 1 Hz and (b) 10 Hz.

Scan size: 1 µm × 1 µm, image size: 512 px × 512 px.

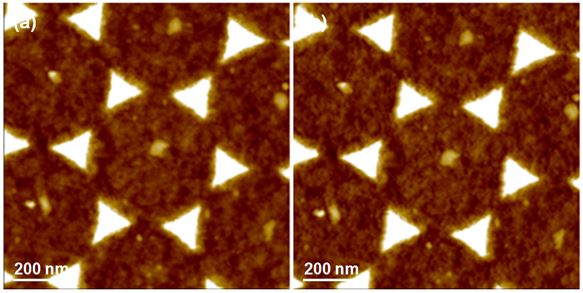

In Figure 2, the sharp edges of the 15 nm high triangular aluminum production pattern can be clearly revealed at both low and high scan speed without sacrificing any image quality. The faster 10 Hz imaging speed allows one to see at a quality equal to the image produced at 1 Hz.

Figure 2. Topography images of the triangular aluminum production pattern imaged at (a) 1 Hz and (b) 10 Hz.

Figure 2. Topography images of the triangular aluminum production pattern imaged at (a) 1 Hz and (b) 10 Hz.

Scan size: 1 µm × 1 µm, image size: 512 px × 512 px.

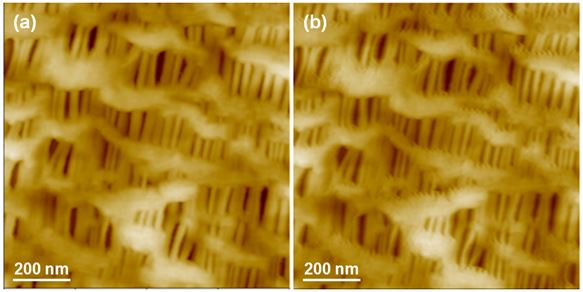

Celgard's porous structure makes it one of the most structurally complex of the three samples scanned with fast imaging. The height variation and the fact that the fibrils are freely suspended make it very challenging to track for conventional techniques. Figure 3 provides us proof that the details of the surface structure were captured perfectly even at the increased speed of 10 Hz.

Figure 3. Topography images of Celgard imaged at (a) 1 Hz and (b) 10 Hz.

Scan size: 1 µm × 1 µm, image size: 512 px × 512 px.

Conclusion

The experiments clearly revealed that the topographies of pentacene, an aluminum projection pattern, and Celgard could be efficiently and accurately imaged at an increased rate of 10 Hz using the Park NX10 AFM system. All Park Systems NX series AFMs can perform fast imaging using high frequency cantilevers without any additional required hardware. We conclude that this built-in feature in all the NX series AFMs from Park Systems will provide researchers with a method to successfully acquire in-situ, real-time critical material surface topography and property change information for their dynamic studies.

REFERENCES

[1] Geochim. Cosmochim. Acta 141, 228-239

[2] Cryst. Growth Des. 15 (1), 129-136

[3] PloS one 9 (4), e95333