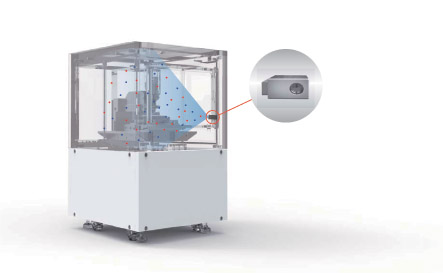

The automated Atomic Force Microscopy (AFM) system for ultra large and heavy flat panel displays at nanoscale

As the demand for Atomic Force Metrology for larger flat panel displays increases, Park NX-Tip Scan Head overcomes nanometrology challenges for samples over 300mm. The Tip Scanning Head and gantry style air-bearing stage allows Park NX-TSH to accurately image roughness measurement, step height measurement, critical dimension measurement.

Atomic force microscopy is the most accurate, and non-destructive, method of measuring samples at nanoscale and with Park NX-TSH, reliable, high resolution AFM images can be obtained on OLEDs, LCDs, photomasks and more.

NX-TSH

Park NX-TSH Specifications

*This specification is customizable. Please consult with Park Systems for more information.

System

Specification

Sample size*

520 mm x 520 mm x 12 mm, 10 kg

Motorized X stage*

travels up to 625 mm, ± 3 µm resolution

Motorized Y stage*

travels up to 525 mm, ± 3 µm resolution

Motorized Z stage*

15 mm Z travel distance, 0.08 µm resolution, < 1 µm repeatability

Motorized Focus Stage*

9 mm Z travel distance for on-axis optics

COGNEX Pattern Recognition

pattern align resolution of 1/4 pixel

Scanner

Performances

XY Range

100 μm × 100 μm

XY Resolution

0.15 nm

Z Range

15 μm

Z Resolution

0.016 nm

AFM and XY Stage

Control Electronics

ADC

18 channels

4 high-speed ADC channels

24-bit ADCs for X,Y and Z position sensor

DAC

17 channels

2 high-speed DAC channels

20-bit DACs for X,Y and Z positioning

Compliances

CE

SEMI Standard S2/S8

Vibration, Acoustic Noise, and ESD Performances

Floor Vibration

< 0.5 µm/s (10 Hz to 200 Hz w/ Active Vibration Isolation System)

Acoustic Noise

>20 dB attenuation w/ Acoustic Enclosure

Facility Requirements

Room Temperature (Stand By)

10 °C ~ 40 °C

Room Temperature (Operating)

18 °C ~ 24 °C

Humidity

30% to 60% (not condensing)

Floor Vibration Level

VC-D (6µm/sec)

Acoustic Noise

Below 65 dB

Pneumatics

Vacuum : -80 kPa

CDA (or N2): 0.7 MPa

Power Supply Rating

208V - 240 V, single phase, 15 A (max)

Total Power Consumption

Consult Park Systems

Ground Resistance

Below 100 ohms

Options

Automatic Tip Exchange (ATX)

Automatic Tip Exchange performs fully automated tip exchanges in order to seamlessly continue automated measurement routines. It automatically calibrates cantilever location and optimizes measurement settings based on measurements of a reference pattern. Our novel magnetic approach to the tip exchange yields a 99% success rate, higher than the traditional vacuum techniques.

Ionization System

Ionization system effectively removes electrostatic charges. It ionizes the charged objects and is very reliable since the system always generates and maintains an ideal balance of positive and negative ions without causing any contamination to the surrounding area. It also reduces the accidental electrostatic built-in charge that may occur during sample handling.

Dimensions & Weight

NX-TSH

2334 mm(w) × 1450 mm(d) x 2450 mm(h), 2720 kg approx. (incl. Control Cabinet)

Ceiling Height: 2500 mm or more

Operator Working Space: 3700 mm (w) x 3000 mm (d), Minimum

The fully Automated Tip Scanning Head for OLED, LCD, and 2D encoder sample

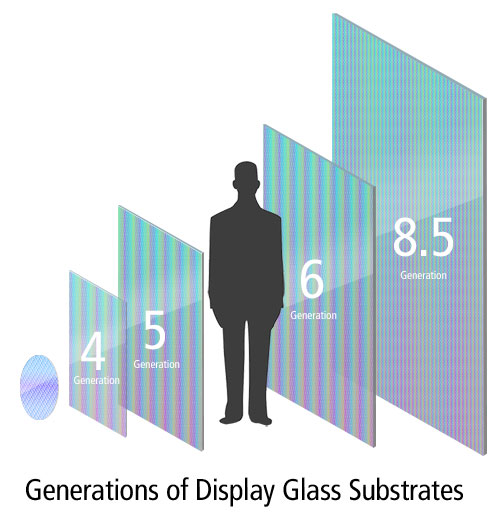

Developed specifically for manufacturers setting up fabs to produce next-generation flat panel displays

Park Systems has scaled up their AFM tools for Gen8+ and all large flat panel displays using Park NX-TSH (Tip Scanning Head) system, and is the fully automated Tip Scan Head for large sample analysis. It was developed specifically for manufacturers setting up fabs to produce next-generation flat panel displays with the objective to overcome the 300mm size threshold limit.

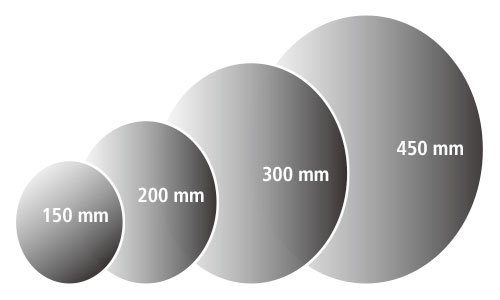

Changes in the silicon wafer diameter

Using conductive AFM, Park NX-TSH can measure the sample surface with optional probe stations that contact the sample surface and provide current into small devices or chips of wafer level. Park NX-TSH is for a 2D encoder sample with conductive AFM for electric defect analysis by integrating micro probe stations.

Park NX-TSH features

Overcomes the limitations of sample size and weight

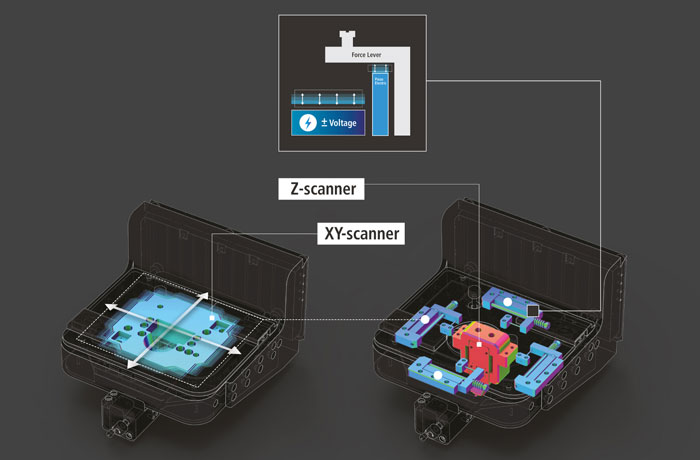

The newly developed Tip Scanning Head by Park Systems combines X, Y and Z scanners, moving directly to the desired point. Park NX-TSH can scan tip itself in X, Y and Z directions, up to 100 µm x 100 μm (x-y direction) and 15 μm Z-direction, and has a flexible chuck to accommodate large and heavy samples over 300mm developed for OLED, LCD for large sample analysis. The sample is fixed on a sample chuck and the tip scanning head attached to the gantry moves to measurement positions on the surface sample. The Park NX-TSH tip scanning head system therefore overcomes the limitations of sample size and weight since the sample is fixed on the sample chuck.

100 µm x 100 µm Flexure-Guided XY Scanner with Closed-loop Control

The XY scanner consists of symmetrical 2-dimensional flexure and high-force piezoelectric stacks that provide highly orthogonal movement with minimal out-of-plane motion, as well as the high responsiveness essential for precise sample scanning at the nanometer scale.

15 µm High Speed Z Scanner with Low Noise Position Sensor

The NX-TSH provides you with unprecedented accuracy in topography height measurement by utilizing its ultra-low noise Z detector instead of the commonly used Z voltage signal that is non-linear in nature. This industry leading low noise Z detector replaces the applied Z voltage as the topography signal.

Long Range Air-bearing XY stage for AFM analysis of industrial samples larger than 300 mm.

Park NX-TSH overcomes nano metrology challenges of large and heavy samples with a Tip Scanning Head and a gantry style air-bearing stage and produces high resolution images. The air bearing stage technology provides faster access and a fully automated system, improving productivity.

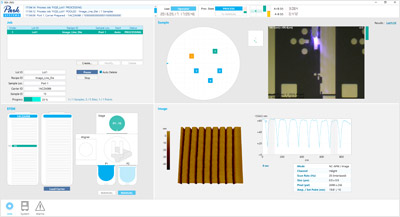

Automatic Measurement Control so you can get accurate scans with less work

The NX-TSH is equipped with automated software that makes operation nearly effortless. Just select the desired measurement program to get precise multi-site analysis with optimized settings for cantilever tuning, scan rate, gain, and set point parameters.

The NX-TSH is equipped with automated software that makes operation nearly effortless. Just select the desired measurement program to get precise multi-site analysis with optimized settings for cantilever tuning, scan rate, gain, and set point parameters.

Park's user-friendly software interface gives you the flexibility to create customized operation routines so you can access the full power of the NX-TSH and get the measurements you need.

Creating new routines is easy. It takes about 10 minutes to make one from scratch, or less than 5 minutes to modify an existing one.

Park NX-TSH’s automated system features:

• Auto, semi-auto, and manual mode so you have complete control

• Editable measurement method for each automated routine

• Live monitoring of the measurement process

• Automatic analysis of acquired measurement data

Productivity meets Accuracy

Automatic Tip Exchange (ATX)

The ATX automatically locates tips by pattern recognition and uses a novel magnetic approach to disengage a used tip and pick up a new tip, with an incredible 99.9% success rate. The laser spot is then automatically optimized along the X- and Y-axis by motorized positioning knobs.

Ionization System for a more stable scanning environment

Our innovative ionization system quickly and effectively removes electrostatic charges in your sample's environment. Since the system always generates and maintains the ideal balance of positive and negative ions, it can create an extremely stable charge environment with little contamination of the surrounding area and minimal risk of accidental electrostatic charge during sample handling.