Our Park AFM technology is very important for determining topology by characterizing morphology, patterns, surface forces, conductivity, thermo-mechanical properties, and other field effects on coatings," states Keibock Lee, President of Park Systems

Our Park AFM technology is very important for determining topology by characterizing morphology, patterns, surface forces, conductivity, thermo-mechanical properties, and other field effects on coatings," states Keibock Lee, President of Park Systems

Santa Clara, CA October 07, 2015

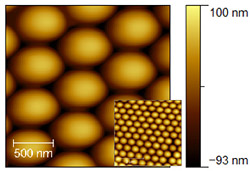

Park Systems, world-leader in atomic force microscopy (AFM) today announced a webinar titled Smart Nanostructured Coatings to provide a comprehensive overview of the innovations in smart coatings using nanoparticle additives on Oct 15, 2015. Register for this free webinar athttp://bit.do/smart-coatings. This webinar will be given by Professor Roberto Advincula, professor with the Department of Macromolecular Science and Engineering at Case Western Reserve University, as part of an ongoing series offered by Park Systems's New Nano Academy, a platform for providing education and shared knowledge on the latest advancements across a wide spectrum of nanosciences. Smart coatings enable improved behaviors based on optical transparency, non-wetting, thermo-mechanical properties, and barrier applications creating a value added benefit for many applications.

"Our Park AFM technology is very important for determining topology by characterizing morphology, patterns, surface forces, conductivity, thermo-mechanical properties, and other field effects on coatings," states Keibock Lee, President of Park Systems. "Park Systems has a long history of technology leadership in AFM and has a reputation as the nanotechnology solutions partner to research and industry because ourTrue Non-Contact Mode, and PinPoint Nanomechanical Mode ensures highest resolution images and most comprehensive data for the ever critical analysis requirements."

AFM can also be used to measure conductivity (conducting AFM), friction forces or tribology (lateral force AFM), and thermo-mechanical properties with nanoindentation. Environmental AFM allows control of the solution or air environment with in-situ analytical methods enabling structure-property and structure-composition-property relationships to be determined.

"Nanostructured Coatings are used in a wide variety of applications of industrial applications, including paints, high barrier packaging and medical applications which are transforming the way we think about coatings," explains Dr. Advincula. "Smart nanocoatings can have aesthetic, sensory, and self-replicating properties in the future, which will give both form and function that is beyond the current applications. A highly desirable coating that can be applied universally is that of a transparent, superhydrophobic, superoleophobic, non-abrasive, and shock-resistant coating."

The future opportunities for utilizing nanoparticle additives include thermo-mechanical stability, abrasion resistance, superhydrophobic effect, anti-reflection properties, self-cleaning, and anti-microbial properties which are enhanced with the introduction of nanoclays or graphene. The use of non-biofouling smart coatings prevents the unwanted adhesion of bacteria and proteins, which may be important for preventing infections. Nanostructured sol-gel coatings and also thin film plasma deposited coatings may be useful for preventing not only fouling, but improved tribological properties.

Nature gives inspired design of smart coatings since these structures can be mimicked with artificial structures or synthetic materials. The result is high value added nanostructured coatings that reflect features for product improvement by the addition of key nanomaterials. There is even interest in dust mitigation for space exploration on the moon for example, where there is a lot of aspheritic and moon regolith that is highly abrasive and reactive. In many cases, thin film coatings that enable protection of any equipment could be possible.

This webinar is available at no cost and is part of Park Systems' Nano Academy, which will offer valuable education and shared knowledge across many Nano Science Disciplines and Industries as a way to further enable NanoScale advancements.

About Park Systems

Park Systems is a world-leading manufacturer of atomic force microscopy (AFM) systems with a complete range of products for researchers and industry engineers in chemistry, materials, physics, life sciences, semiconductor and data storage industries. Park's products are used by over a thousand of institutions and corporations worldwide. Park's AFM provides highest data accuracy at nanoscale resolution, superior productivity, and lowest operating cost thanks to its unique technology and innovative engineering. Park Systems, Inc. is headquartered in Santa Clara, California with its global manufacturing, and R&D headquarters in Korea. Park's products are sold and supported worldwide with regional headquarters in the US, Korea, Japan, and Singapore, and distribution partners throughout Europe, Asia, and America. Please visit http://www.parkafm.com or call 408-986-1110 for more information.

About Prof. Rigoberto Advincula

Title: SmartNanostructured Coatings

Date: Oct. 15, 2015

Time: 9am PST

To register go to: http://bit.do/smart-coatings

About Prof. Rigoberto Advincula

Prof. Rigoberto Advincula, Director of the Petro Case Consortium, is recognized industry-wide as an expert regarding polymer and materials challenges of the oil-gas industry. He is currently a Professor with the Department of Macromolecular Science and Engineering at Case Western Reserve University and is the recipient of numerous awards including Fellow of the American Chemical Society, Herman Mark Scholar Award of the Polymer Division, and Humboldt Fellow.