Imaging a Narrow Area Using a Park AFM Instrument

Case study: Cross-section of a Polymer Film

By H.-Y. Nie

The University of Western Ontario

The surface of a biaxially-oriented polypropylene (BOPP) film is characterized by a fiber-like network, which is determined by the draw ratios at the two orthogonal directions, i.e., machine-direction (MD) and transverse-direction (TD). The surface morphology of such a film has been studied with atomic force microscopy (AFM). To fully understand and characterize these materials, it would be beneficial to find out whether this structure goes through the entire thickness of the film. Using a Park Systems’ AFM one can easily address this question by imaging the cross-section of a BOPP film. The probe tip approach to the surface combined with excellent optical views makes such tasks trivial.

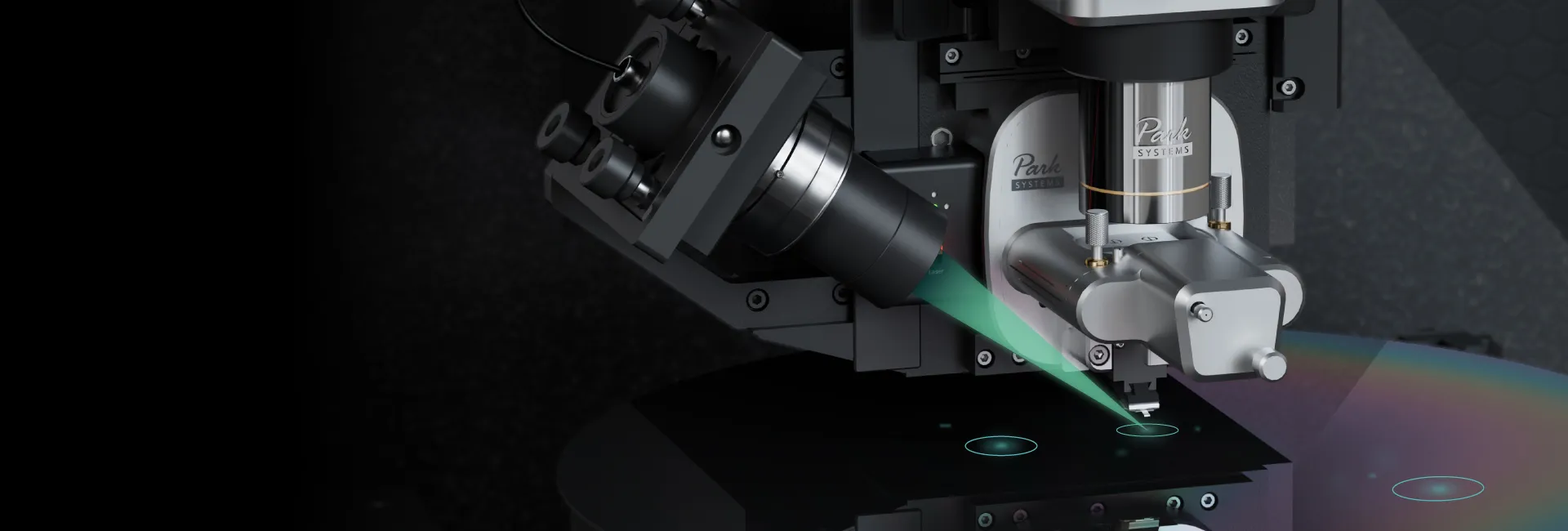

The Park AFM series have a separate sample stage for the X-Y scanning from the Z-scanner for height measurement. The lens (features are magnified ~780x on a 19" monitor) for a CCD camera can move together with the z-scanner in the vertical direction; this is used for the cantilever to quickly travel a long distance and become very close to the sample surface (say, a couple of mm). Once the cantilever gets nearby to the sample surface, the lens can be set to move alone so that the sample surface is focused before the cantilever is set to engage to the working distance from the sample surface. The ease of landing the tip on a narrow sample surface is well suited for imaging cross-section of a thin sample. We demonstrate this by imaging cross-section of a BOPP film which is ~30 µm thick.

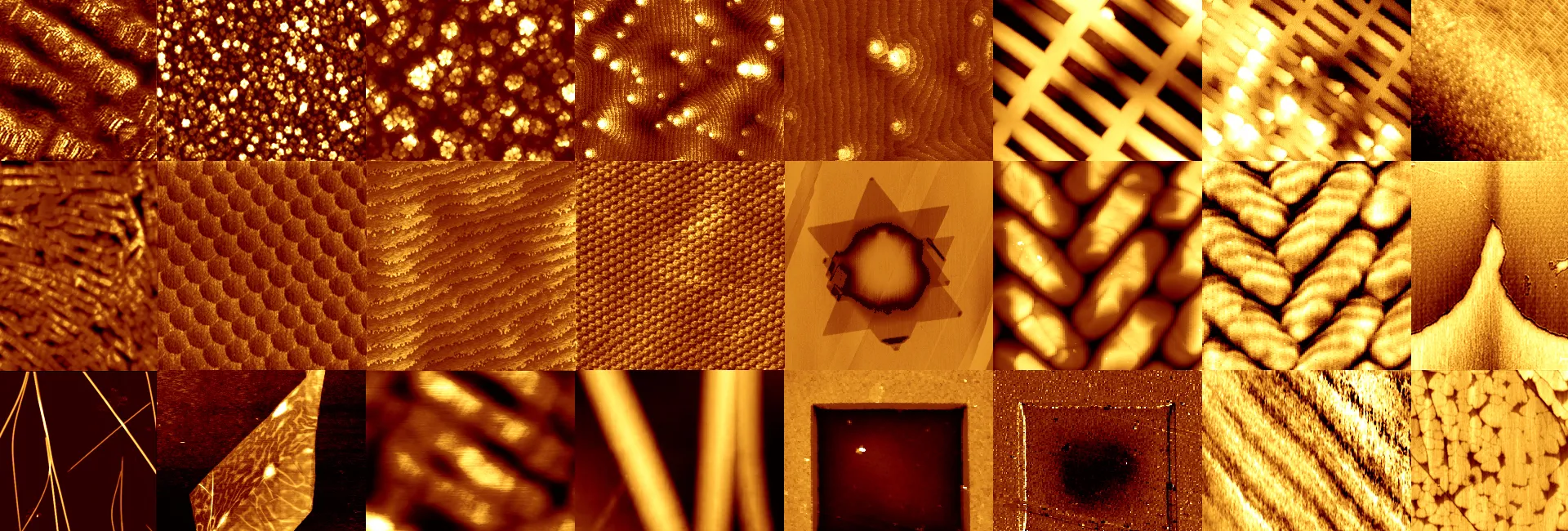

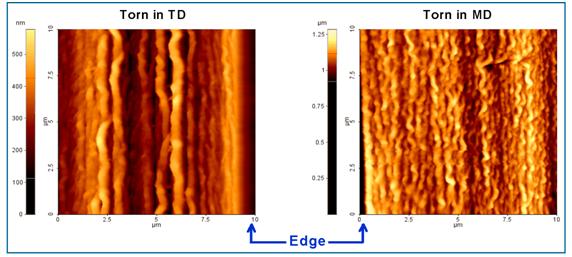

Figure 1. The cross-section images of BOPP film torn in (a) transverse-direction (TD) and (b) machine-direction (MD), respectively.

The cross-section of a BOPP film was achieved by first making a cut along the MD (or TD) followed by precisely tearing the film in that direction. The specimen was mounted on an adopter by sandwiching the film between the two metal plates of the adopter. This adopter is then placed on the sample stage such that the BOPP film would be proximately under the cantilever. Then the Z-scanner and the lens (the cantilever was focused) were lowered together towards the sample surface. This coarse approach was stopped when the cantilever-sample distance was shortened to a couple of mm. Then, one lowers the lens alone further towards the sample surface to focus on the sample surface only (viewed through the CCD camera monitor). The sample position may then be optimized such that a good area to scan is achieved. After having located the sample surface, the cantilever was brought into view by lowering the Z-scanner. This step was well controlled until the cantilever image became clear (i.e., to prevent the contact between the tip and the sample surface). Then the approach process was started to engage the tip to the working distance from the sample surface; this is regulated by the set point, which is either a contact force in contact mode or a distance corresponding to the damping of the oscillation of the cantilever in True Non-Contact mode.

Shown in Figure 1 are 10 µm x 10 µm area scans in True Non-Contact mode for cross-sections of a BOPP film achieved by tearing the film in MD (a) and TD (b), respectively. The edge of the cross-section of the film is also indicated. As easily noticeable, there is a well-defined layered structure along the scan direction. Therefore, it has been directly confirmed that the layered structure goes through the entire thickness of the BOPP film taken under investigation. It is also interesting to note that the structure appears to be different for the two samples made by tearing the film in MD and TD, respectively. Additional investigation is ongoing.

Note

An application note for PSIA by H.-Y. Nie at Surface Science Western, Room G-1 WSC, The University of Western Ontario, London, Ontario, Canada N6A 5B7,http://www.uwo.ca/ssw