Limitations of Conventional 3D AFM

|

|

Flare Tip |

|

Tilted Step-in Tip |

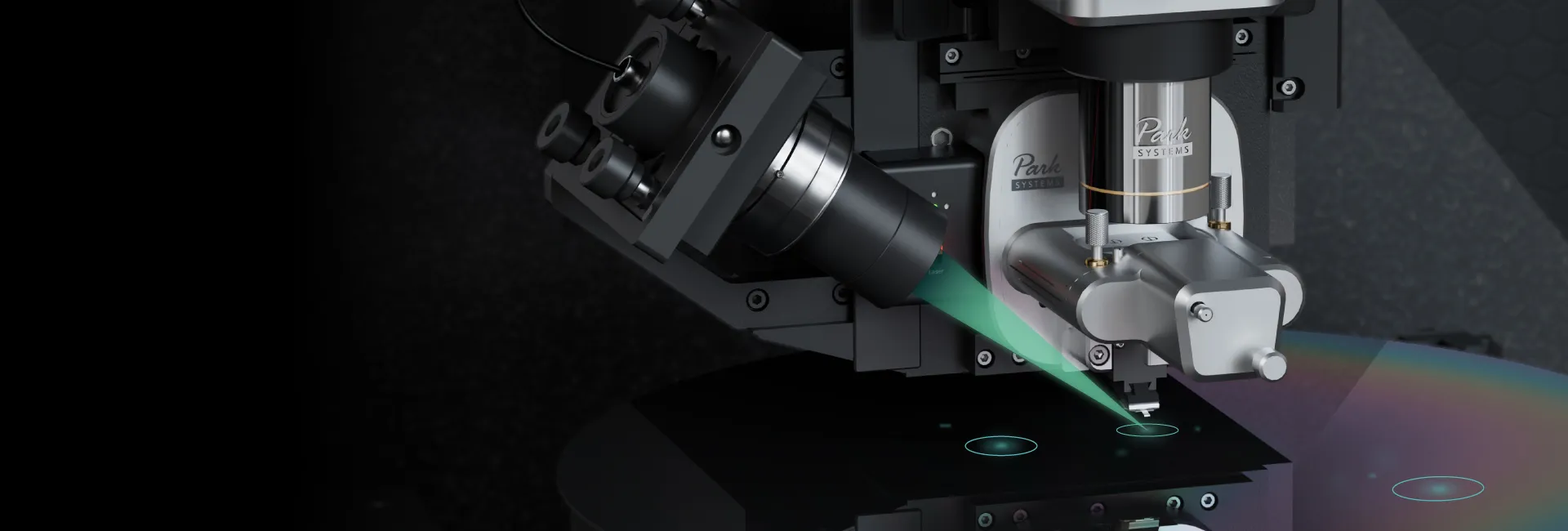

Innovative XE-3DM Technology Overcomes the Challenges

|

|

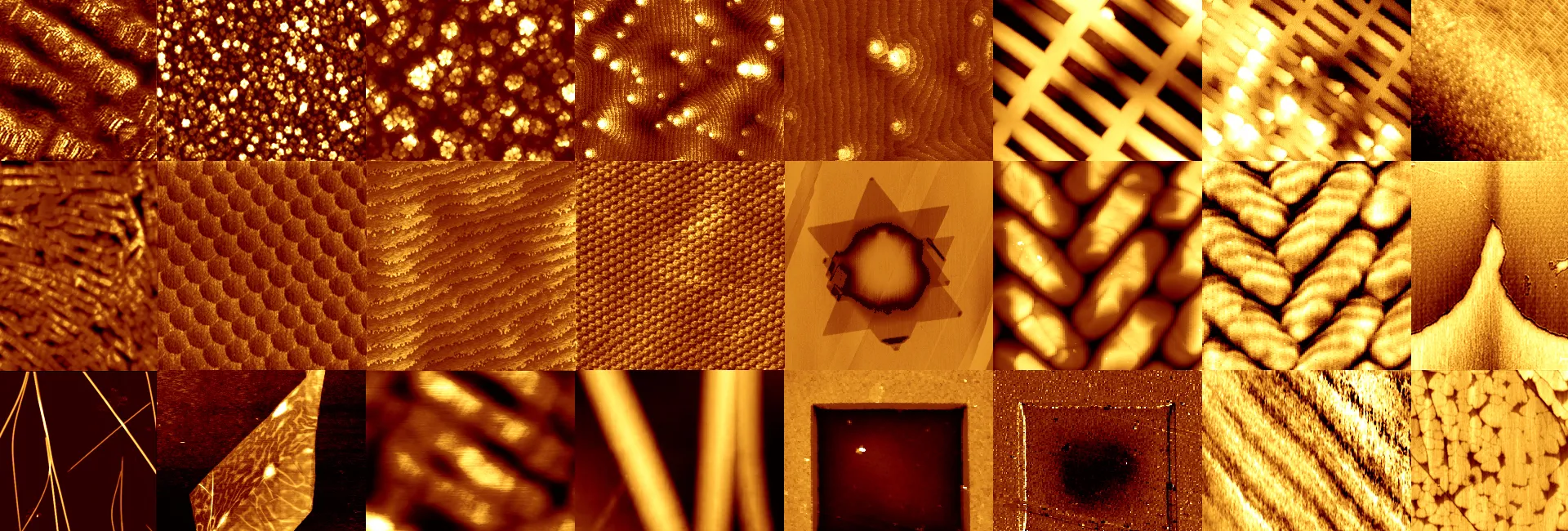

High Resolution Access to Undercut and Sidewall

|

Image of Undercut Overhang: Metal Overhang Structure

|

|

3D View of High Resolution Sidewall Scan

|

Complete 3D Metrology of Sidewall |

|

Sidewall Roughness Measurement

|

|

Undercut & Sidewall Characterization

|

|

- Need to measure the sidewall roughness, angle and the width of bottom, middle, and top |

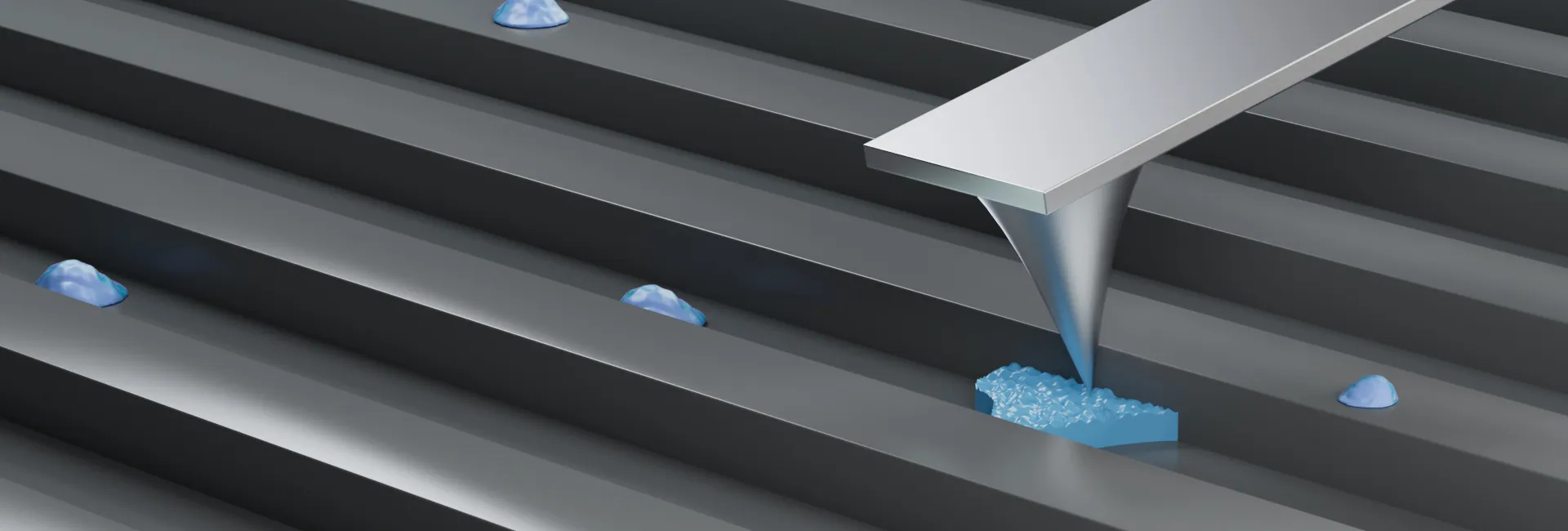

Challenges in Accessing Sidewall

|

|

Conventional AFM cannot get access to the sidewall, especially for overhang features |

|

Other methods, such as the flare tips, are insufficient in obtaining the high resolution details of the sidewall due to its dull tip. For a deeper overhang, the bottom width cannot be reached at all. |

For Undercut Characterization and Sidewall Metrology

Continuing the company’s impressive track record of developing optimized solutions, Park Systems introduces XE-3DM, an automatic AFM which revolutionizes the way trench, overhang, and undercut features are scanned and analyzed. The new XE-3DM also makes possible to image soft photoresist structures without deforming or damaging it.

|

Advanced Inline Automation Features |

Flat and very wide bottom portion of the tip (>100nm)

Flat and very wide bottom portion of the tip (>100nm)